Highest precision for pharma

Our application areas have a fascinating variety

API (Active Pharmaceutical Ingredients)

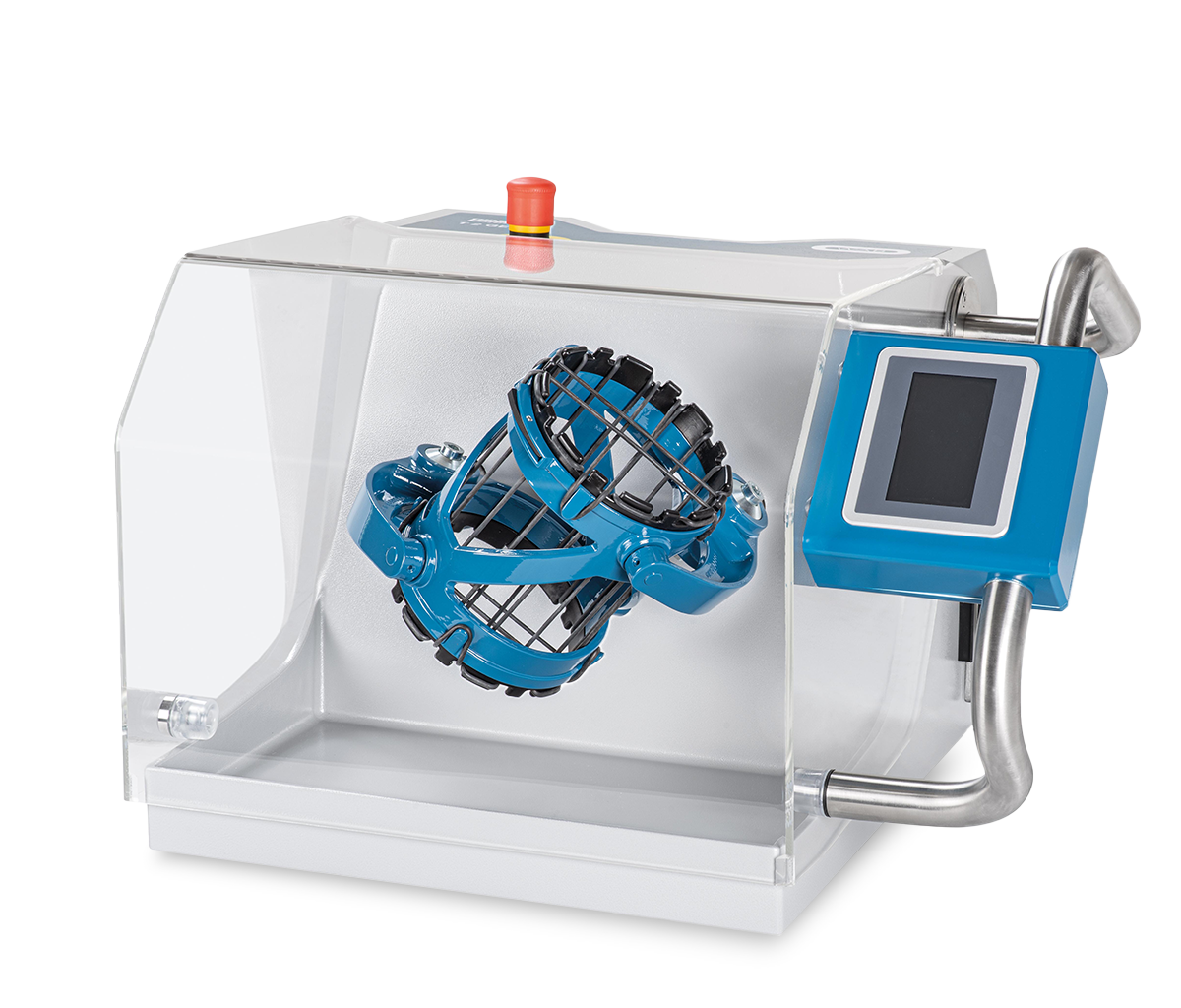

Mixing Technology

Proper mixing and homogenization of APIs is critical to ensure the efficacy, safety and quality of the final products. This is ensured by means of our three-dimensional shaker mixers.

Flow Chemistry

The production of individual APIs in a continuous process using our WAB IMPA°CT REACTOR opens up new possibilities. Reactions can now be carried out in combination with solid, liquid and gaseous reactants. Flow Chemistry enables a continuous product flow and a residence time tailored to the product within the WAB IMPA°CT REACTOR. Excellent surface renewal enables particularly efficient activation of reactants and catalysts, which in turn reduces overall energy requirements. Due to the increased efficiency of the reaction, the use of solvents can be reduced or even eliminated.

Ophthalmic

With our agitator bead mills, the solid active ingredients are finely ground and dispersed in a liquid solution. The particle size distribution achieved in this way improves the solubility of the active ingredients, increases bioavailability and compatibility within the body and ensures uniform distribution of the active ingredient. This improves the consistency of eye drop dosage.

Dermal

With our agitator bead mills, the solid active ingredients are finely ground and dispersed in a liquid solution. The particle size distribution achieved in this way improves the solubility of the active ingredients, increases bioavailability and skin permeability, regulates the absorption rate and ensures an even distribution and absorption of the active ingredient.

Vaccines

Vaccines are often produced from attenuated or killed microorganisms, parts of microorganisms or recombinant proteins. In order to use the immunostimulatory components for vaccine action, they must be extracted from the source cells. These components are obtained by disrupting the cells using a agitator bead mill.

Inhalation

With our three-dimensional shaker mixers the active pharmaceutical ingredients are perfectly homogenized with the carrier material. This ensures that the active ingredient is evenly distributed throughout the batch.

Injectables

With our agitator bead mills, the solid active ingredients are finely ground and dispersed in a liquid solution. The resulting particle size distribution improves the solubility of the active ingredients, increases the bioavailability within the body and ensures a uniform distribution of the active ingredient. This improves the consistency of injectables during dosing.

Metal Organic Frameworks

The application Metal Organic Frameworks (MOFs) is a growing field of research in the pharmaceutical industry that has the potential to revolutionize the way drugs are developed, delivered and used. MOFs are extremely interesting due to their large surface area and precisely adjustable properties. MOFs can be produced with agitator bead mills from WAB-GROUP or the WAB IMPA°CT REACTOR.

Ear remedies

With our agitator bead mills, the solid active ingredients are finely ground and dispersed in a liquid solution. The particle size distribution thus achieved improves the solubility of the active ingredients, increases bioavailability within the body and ensures uniform distribution of the active ingredient. This improves the consistency of the dosage of ear drops.

Oral

With our agitator bead mills, the solid active ingredients are finely ground and dispersed in a liquid solution. The particle size distribution thus achieved improves the solubility of the active ingredients, increases bioavailability within the body and ensures uniform distribution of the active ingredient. This is the prerequisite for the downstream process steps for production of preparations.

Plastic surgery

Our three-dimensional shaker mixers are used in plastic surgery to bring various biomaterials to an injectable consistency.

Dilution/Potentiation

Mixing and dilution or potentiation are fundamental steps in the preparation of homeopathic medicines as well as in the preparation of solutions used in various medical applications. These procedures play a crucial role in adjusting the concentration of active ingredients and in the production of preparations used for the treatment of diseases and the promotion of health.

Veterinary medicine

In veterinary medicine, our agitator bead mills are used in the production of medicine for animals. A stable suspension contributes to distribute the drugs evenly, improve intake and absorption, and increase bioavailability.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our comprehensive portfolio is sure to contain the ideal model for your most demanding product.

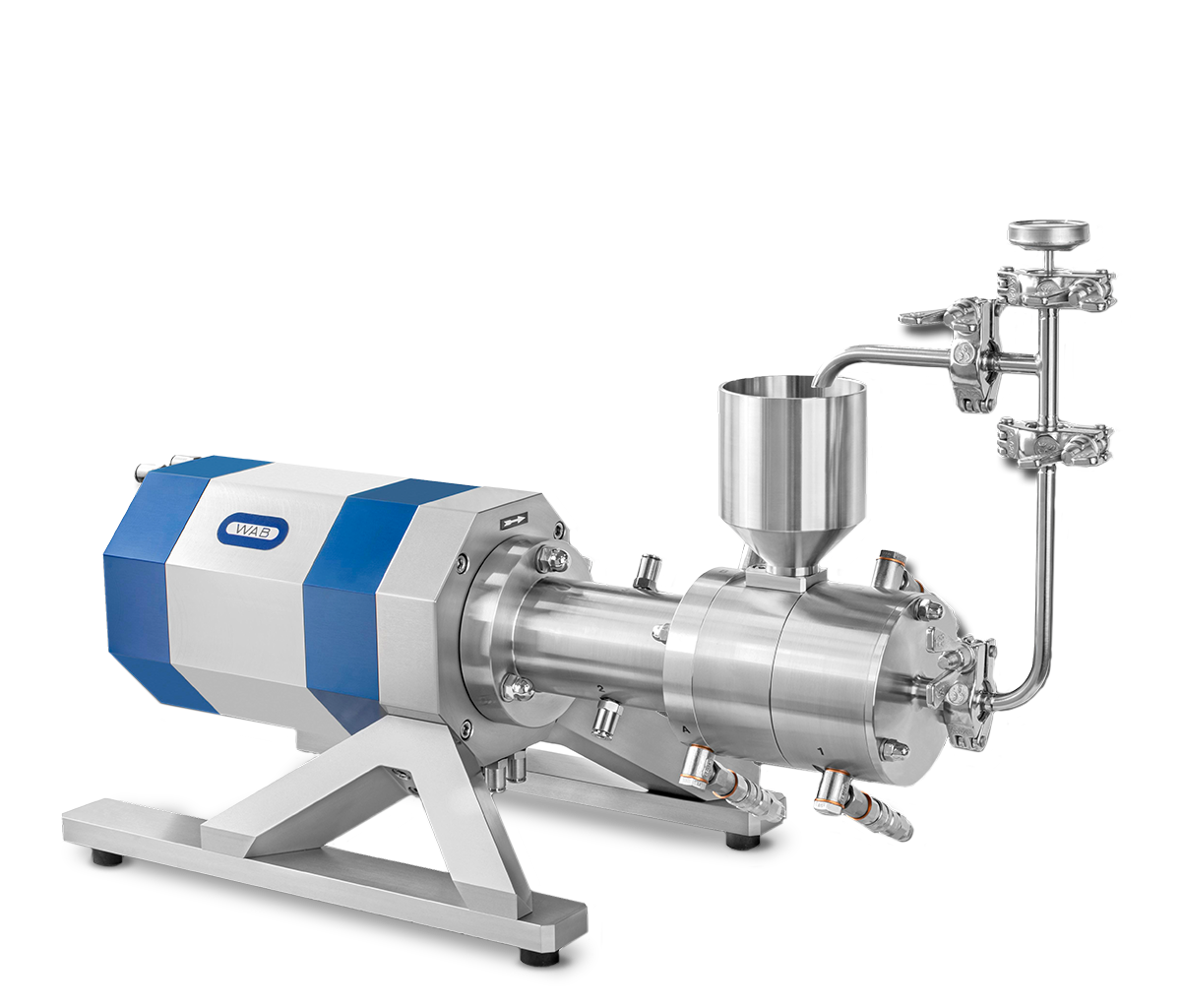

Mechanochemical reactor

WAB IMPA°CT REACTOR

An inductively heated mechanochemical reactor for continuous mechanochemistry

Laboratory Agitator Bead Mill

DYNO-MILL UNI LAB

The laboratory agitator bead mill enables the use of DYNO-MILL UBM and ECM-AP technology and is ideal for R&D

Universal Agitator Bead Mill

DYNO-MILL UBM

Efficient dispersion and fine grinding solutions for your products

Special Agitator Bead Mill

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Laboratory Agitator Bead Mill

DYNO-MILL MULTI LAB

The laboratory agitator bead mill is flexible in terms of grinding chamber size, material selection and grinding technology

Disc Agitator Bead Mill

DYNO-MILL KD

The mill is suitable for numerous applications and all types of grinding media materials

Laboratory Agitator Bead Mill

DYNO-MILL ECM-AP 05

The high-performance laboratory mill produces the finest and narrowest particle distributions down to the nanometer range

High-Performance Agitator Bead Mill

DYNO-MILL ECM-AP

The ideal agitator bead mill for high throughputs and highly viscous products

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.

"*" indicates required fields