Grinding and dispersion technology

Universal Agitator Bead Mill

DYNO-MILL UBM

Efficient dispersion and fine grinding solutions for your products

Industries

Reliable partner for your processes

Over 60 years of experience and leading technologies combined in one series: DYNO-MILL Universal Bead Mill (UBM).

The new generation of WAB-GROUP agitator bead mill covers the entire range from dispersion to ultra-fine grinding of small product quantities in the laboratory to the production of large quantities. The machine series meets the requirements of the industry in terms of efficiency, reliability and operating costs.

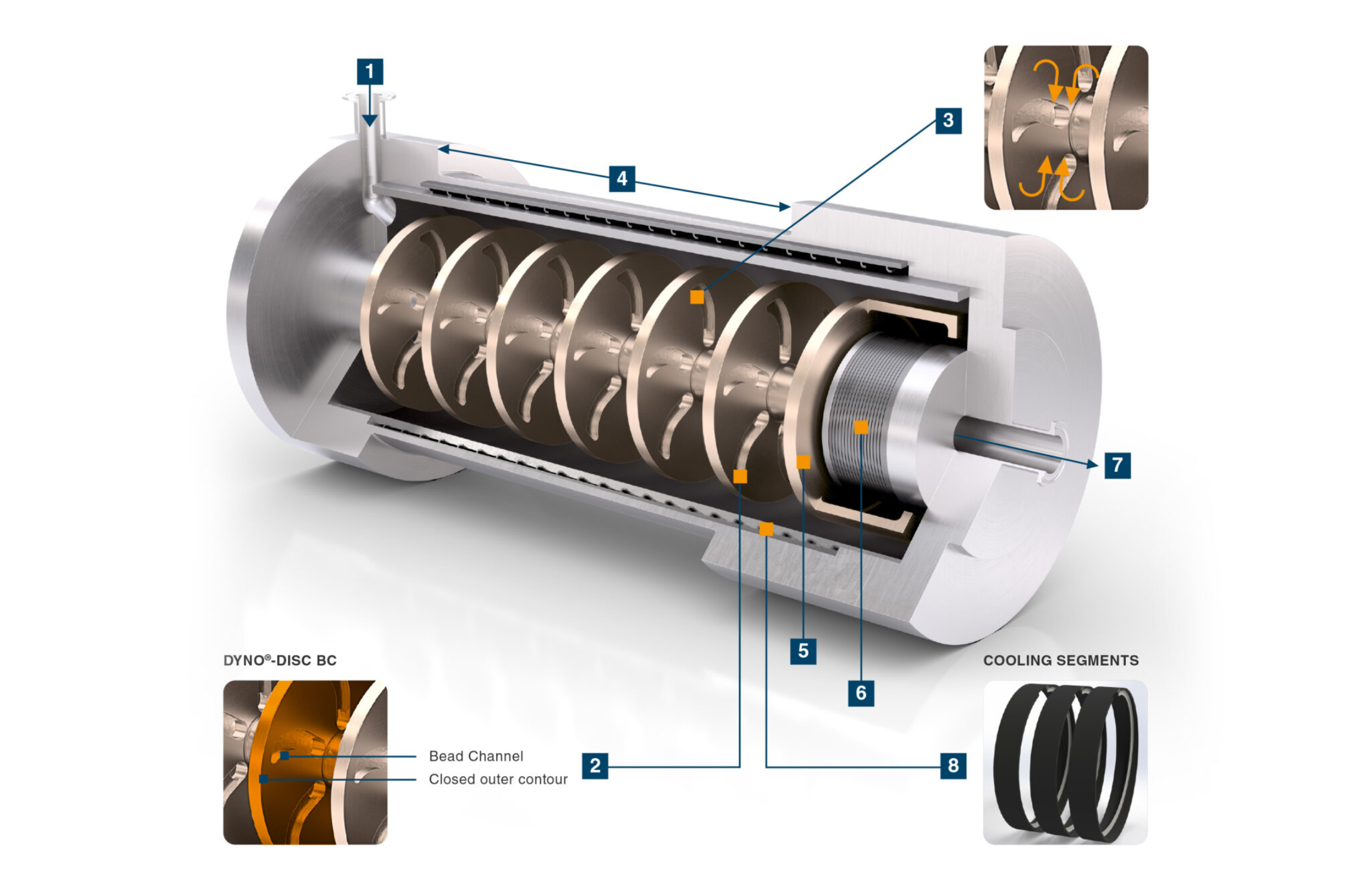

Functionality

The latest generation of DYNO-DISC BC agitator discs have been specially developed for this series. They are characterized by unique grinding media channels and a closed outer contour. The grinding media channels ensure efficient acceleration of the grinding media along a precisely defined path. During operation, each of the grinding media channels creates two efficient grinding circuits between the DYNO-DISC BC agitator discs, which operate in opposite directions.

Novel grinding chamber system

- Product inlet

- DYNO-DISC BC (Bead Channel)

- Grinding circuits that operate in opposite directions

- Even distribution of the grinding beads in the active grinding chamber

- DYNO-ROTOR BS (Bead Separation)

- Screen for high throughputs

- Product outlet

- Cooling segments

Features

The grinding chamber is at an ideal working height and allows quick and ergonomic cleaning operations. After opening, the grinding media are emptied into a robust stainless steel channel firmly connected to the machine housing. From there, they can be conveniently filled into other containers.

The high wear resistance of the DYNO-MILL UBM extends maintenance cycles and thus reduces maintenance costs. Together with the unbeatable WAB-GROUP machine service, this mill generation achieves high machine availability!

- Suitability for high throughputs and highly viscous products due to large screen passage areas

- Long screen life

- Sieve change possible without opening the grinding chamber

- Suitability for passage and circuit operation

- Wide variety of materials to choose the optimal machine equipment

- Use of ø 0.2-2.5 mm grinding media

- Grinding chamber volume from 0.5-100 l

- Low-maintenance, double-acting mechanical seal for highest demands

- Closed machine housing

- Low noise level

- Wide range of control solutions

Customized solutions

Our experience helps us to meet your process needs for projects with different and special requirements and to offer you a tailor-made solution such as the agitator bead mill DYNO-MILL Pharma.

Download

Find more information about our universal agitator bead mill in compact form as PDF file. Efficient dispersion and ultra-fine grinding for your products.

Technical specifications

| Type | DYNO-MILL UNI LAB | DYNO-MILL UBM 5 | DYNO-MILL UBM 20 | DYNO-MILL UBM 50 | DYNO-MILL UBM 100 |

|---|---|---|---|---|---|

| Grinding chamber volume (liters) | 0.53 | 6.0 | 19.6 | 55.3 | 94.4 |

| Active grinding chamber volume (liters) | 0.41 | 5.2 | 17.4 | 50.6 | 86.6 |

| Mill drive (kW) | 4 | 11 | 37 | 55 | 90 |

| Cooling water throughput (L/h) | 250 - 400 | 600 - 1000 | 800 - 2000 | 2000 - 4000 | 2500 - 4500 |

| Weight (kg) | 120 - 140 | 750 - 850 | 1150 - 1250 | 1900 - 2100 | 2800 - 3100 |

| Dimension L x W x H (mm) | 895 x 725 x 730 | 1630 x 865 x 1650 | 1185 x 1025 x 1800 | 2265 x 1290 x 2080 | 2560 x 1305 x 2270 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.

"*" indicates required fields