Mixing Technology

3D Shaker Mixer

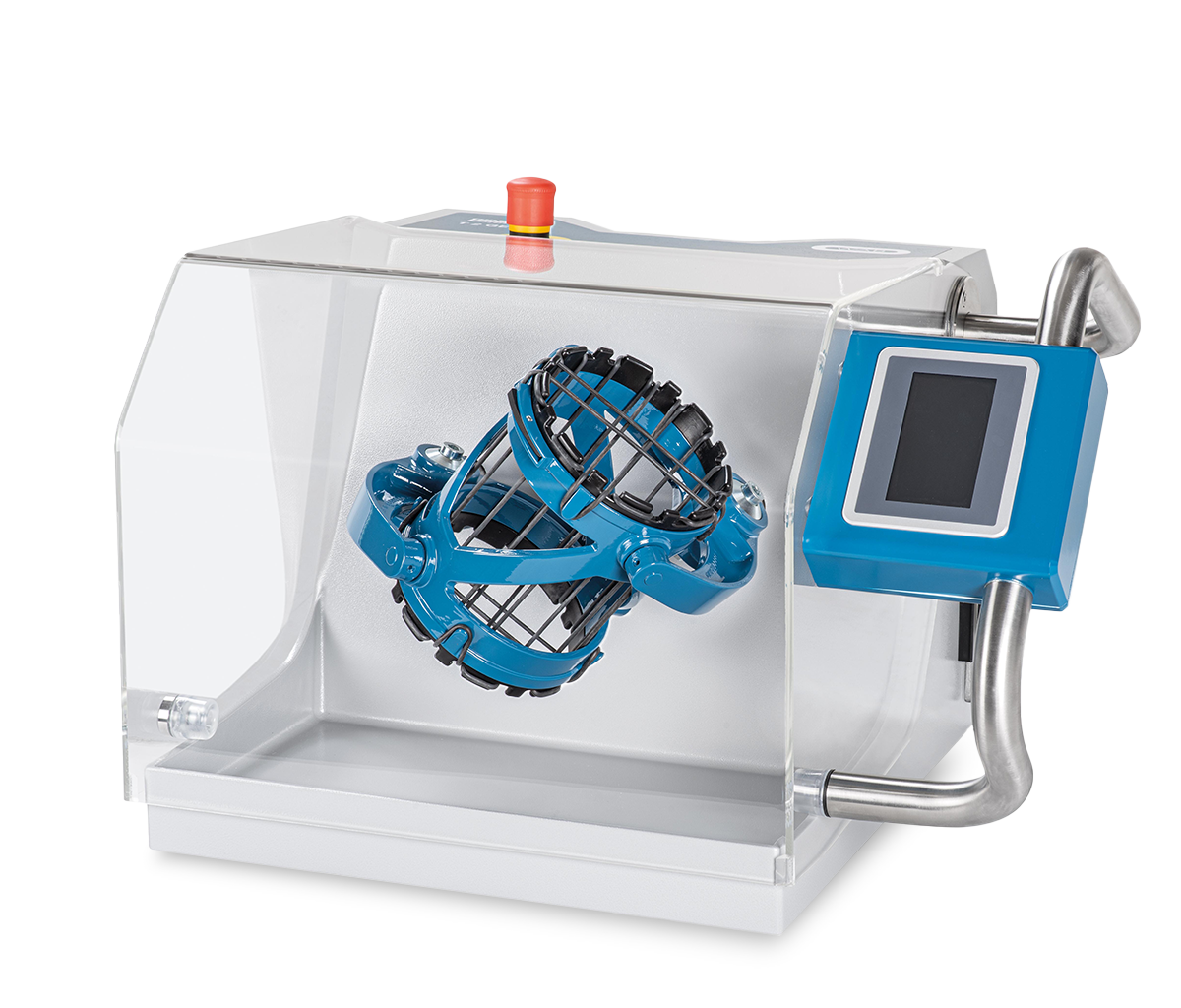

dyna-MIX

3D shaker mixer for tank volumes from 40-1000 liters

Industries

For a homogeneous mixture

The dyna-MIX mixes solids, solids with liquids and liquids. It is used when high-quality mixing results are required for higher quantities.

Its robust design also allows the processing of larger material quantities with high specific weights. A high-quality control system always ensures reproducible and extremely homogeneous mixing results.

Functionality

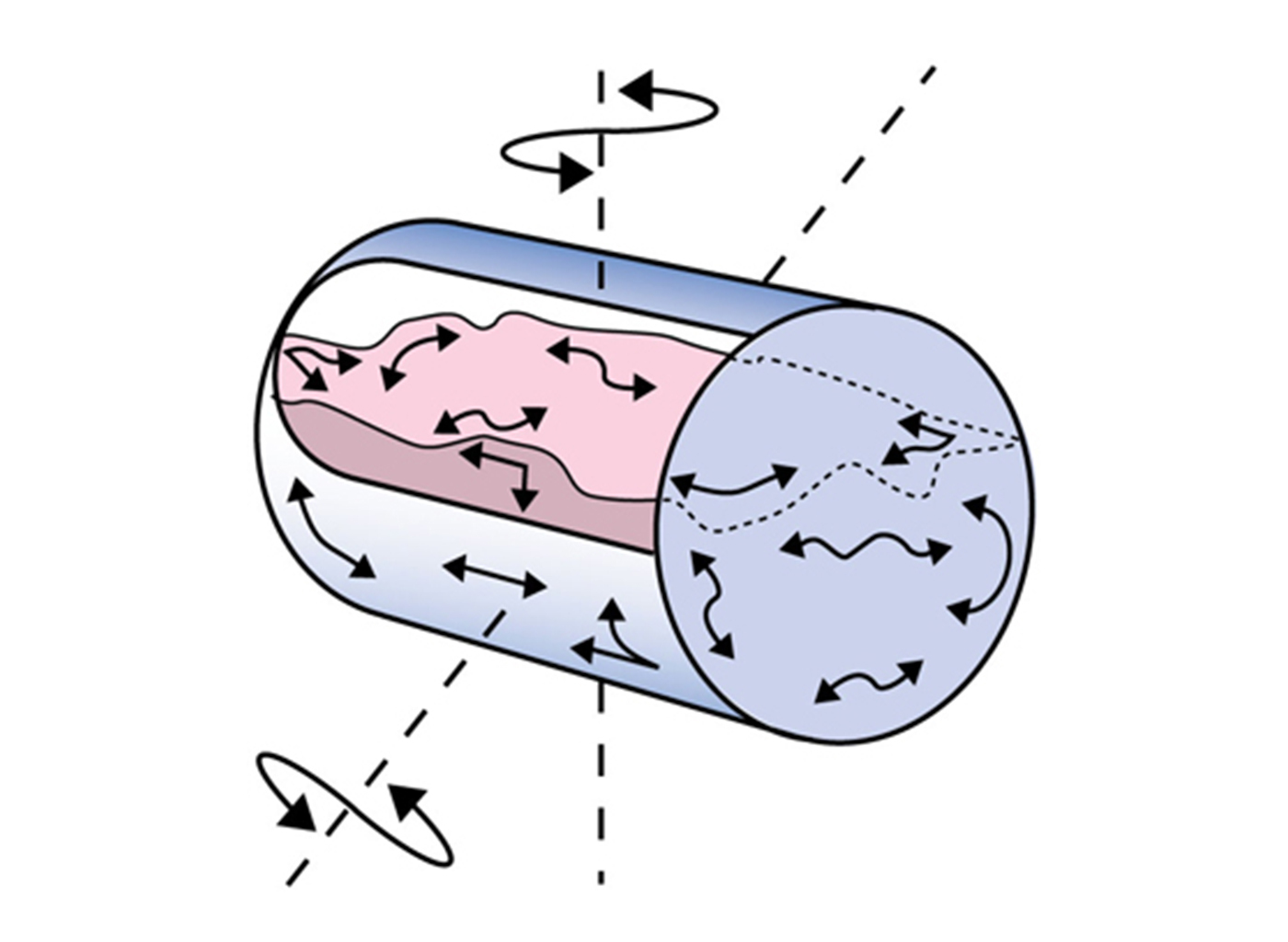

The principle of the patented dyna-MIX 3D shaker mixer is based on a precisely controlled three-dimensional movement. The required motion paths are programmed in detail into the mixer's control module. The control system regulates the motion sequence of the cardanically suspended mixing vessel and ensures exact implementation of the three-dimensional mixing movements.

The mixing movements of the dyna-MIX enable gentle, uniform and always reproducible mixing processes. The mixing containers are held securely in a fixed clamping device. On request, we can adapt the fixed clamping device to special requirements.

Features

- Achieving the highest mixing qualities

- Efficient and gentle mixing processes

- PLC control and data acquisition of process parameters with recipe storage

- Existing mixing containers can usually be reused

- No additional cleaning effort

- Quick mixing bowl change

- No contamination and no emissions

- Fixed clamping device with individual adaptation to the mixing containers

- Low basic noise of the mixer

Download

Find more information about our 3D shaker mixer in compact form as PDF file. High reproducibility and exceptional homogeneity.

Technical specifications

| Type | CM 100 | CM 200 | CM 500 |

|---|---|---|---|

| Useful volume (l) | 32-80 | 80-200 | 240-520 |

| Container volume (l) | 40-100 | 100-250 | 300-650 |

| Max. load (kg) | 200 | 400 | 900 |

| Rotational speed (rpm)* | 0-30 | 0-30 | 0-25 |

| Power drive (kW) | 3 | 4 | 5,5 |

| Power drive inner axis | 1,1 | 1,5 | 2,2 |

| Total connected load required (kW) | 5 | 7 | 11 |

| With lifting frame | No | No | Yes |

| Min. load capacity per supporting point (kg) | 300 | 400 | 1250 |

| Empty weight (kg) | 1200 | 2000 | 4600 |

| Dimension L x W x H (mm) | 2450 x 1600 x 1550 | 2950 x 2100 x 1940 | 4350 x 3100 x 2600 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.