Grinding and dispersion technology

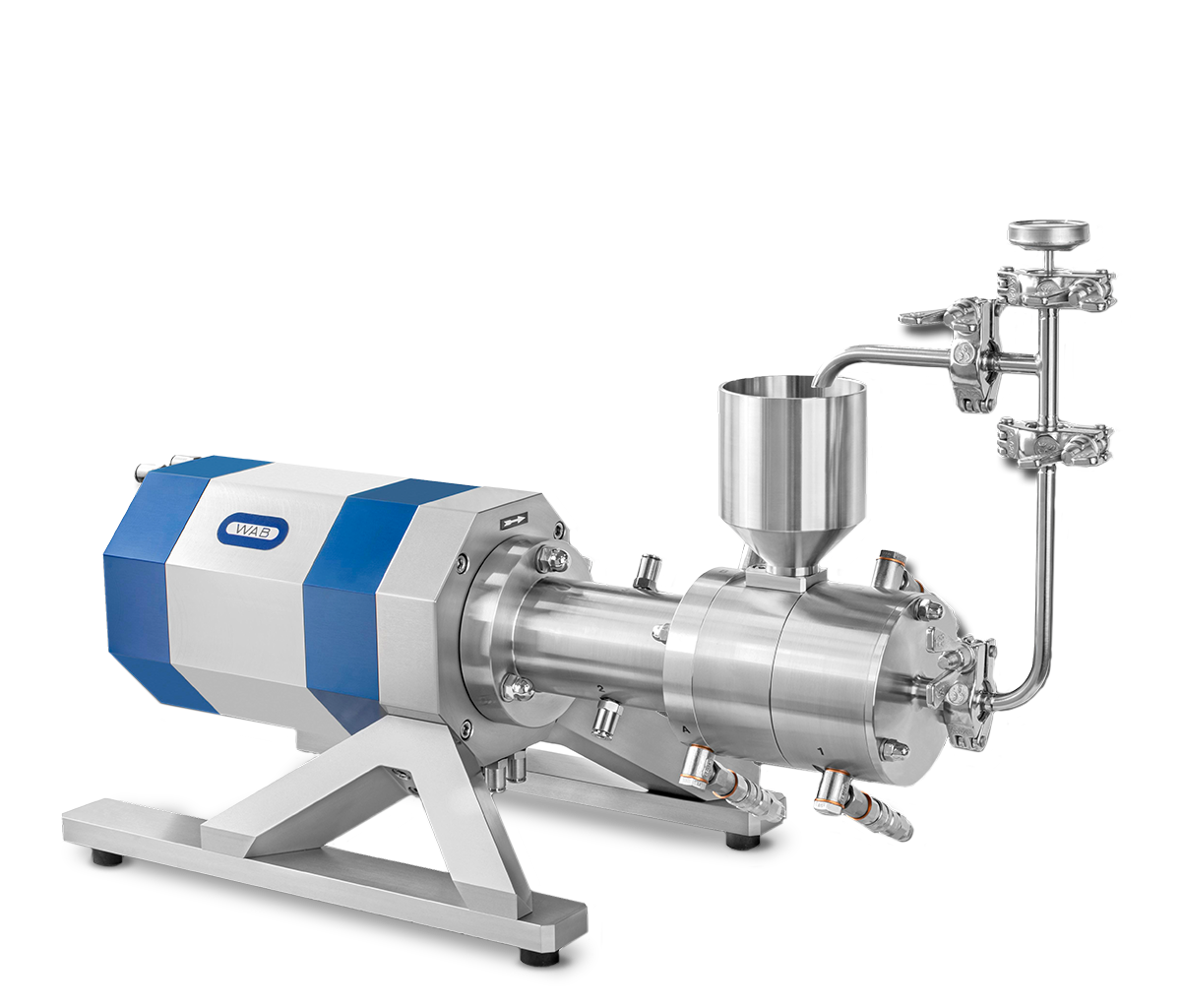

Disc Agitator Bead Mill

DYNO-MILL KD

The mill is suitable for numerous applications and all types of grinding media materials

Industries

The first horizontal agitator bead mill

The original agitator bead mill from WAB-GROUP is a true multi-talent.

By consistently expanding the variety of materials, the material quality and, if necessary, by adapting the DYNO-MILL KD models to highly specialized customer requirements, this type of agitator bead mill has been used in many applications for decades since today. The DYNO-MILL KD disc mills are available with grinding chamber volumes from 0.15 to 600 liters and are suitable for virtually all types of grinding media materials.

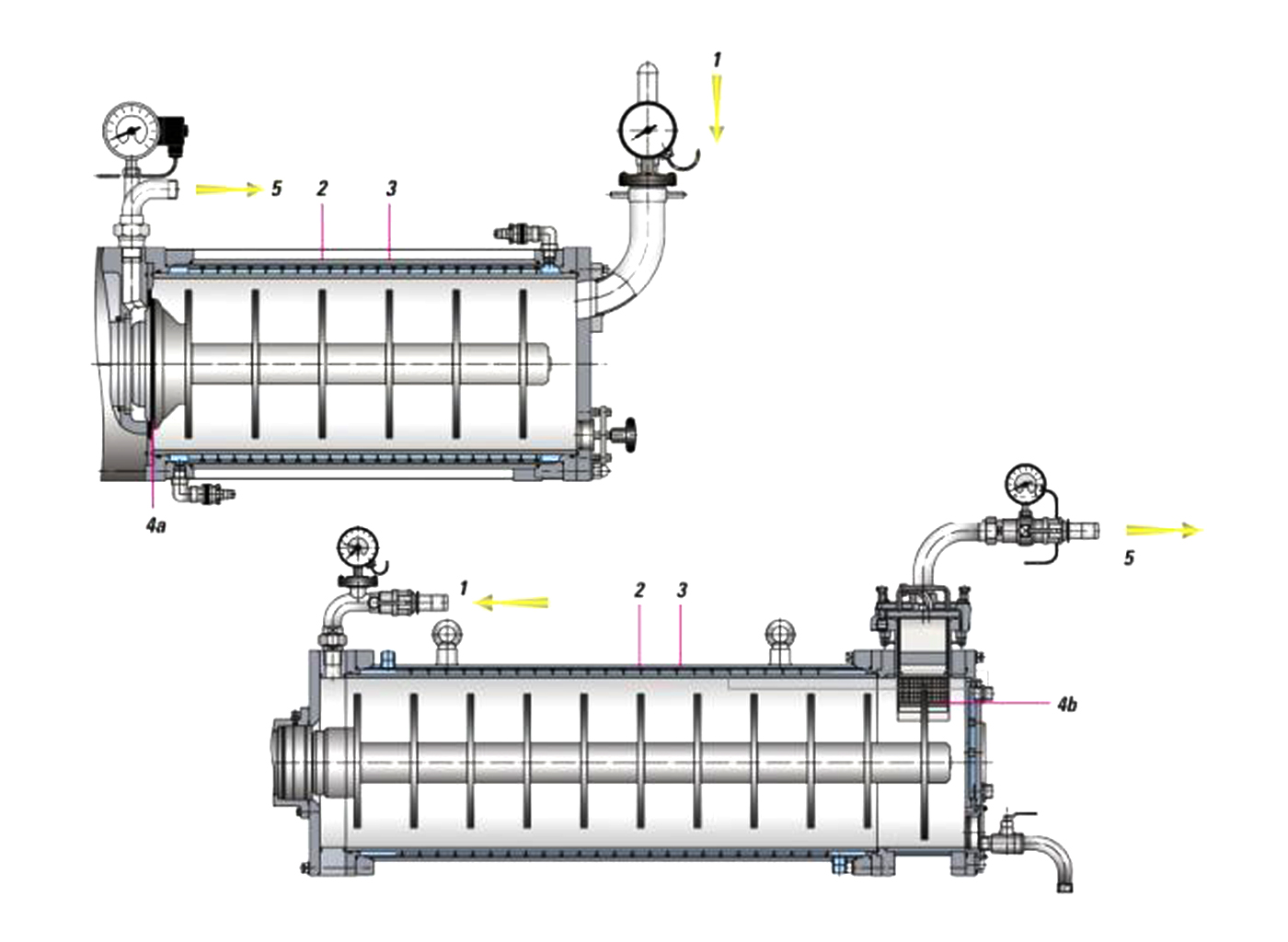

Functionality

In the horizontal grinding chamber, the specially shaped DYNO agitator discs are arranged symmetrically on the agitator shaft. They transfer the kinetic energy required for grinding to the grinding media. Especially in the passage mode, together with the right process parameters, these disc mills still achieve outstanding grinding results even today.

The specific design of the individual machine models depends on the grinding chamber volume. The models DYNO-MILL KD 20 to DYNO-MILL KD 60 are optionally available with a dynamic friction gap separator or a screen separation system.

Proven grinding chamber system

- Product inlet

- DYNO agitator discs in various materials

- Coolable grinding container with replaceable grinding cylinder

- a Dynamic gap separator

b Screen separator - Product outlet

Features

- Ideal for passage mode with constant efficiency and for reaching with the narrowest grain size distribution

- The ideal equipment for every product with the selection of a wide range of materials for the wear parts in contact with the product

- Grinding media sizes from ø 0.5-2.5 mm

- Ideal cooling properties: The forced guidance of the cooling water in the outer jacket allows the processing of temperature-sensitive products

- Easy handling - each DYNO-MILL KD can be disassembled in just a few steps and a quick changeover to a different mill configuration is guaranteed

- Easy operation and setting of operating parameters

- Scale-up to all machine sizes of the DYNO-MILL KD series due to consistent grinding concept

- Low operating and maintenance costs

Customized solutions

Our experience helps us to meet your process needs for projects with different and special requirements and to offer you a tailor-made solution such as the agitator bead mill DYNO-MILL Pharma.

Download

Find more information about our disc agitator bead mill in compact form as PDF file. Proven a thousand times in the field of dispersion and ultra fine wet grinding.

Technical specifications

| Type | MULTI LAB | ECO5 | KD 6 (6) | KD 6 (8) | KD 20 B | KD 20 BS | KD 25 | KD 25 S | KD 45 D | KD 45 DS | KD 60 | KD 60 S | KD 120 A | KD 190 A | KD 280 A | KD 600 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Grinding media separation gap | x | x | x | x | x | x | x | x | ||||||||

| Grinding media separation screen | x | x | x | x | x | x | x | x | ||||||||

| Grinding chamber volume (liters) | 0.15-1.4 | 5 | 6 | 8 | 16,5 | 18 | 25 | 26 | 46 | 49 | 60 | 62 | 128 | 196 | 296 | 612 |

| Capacity range (l/h) | 1-50 | 20-200 | 20-150 | 20-200 | 70-500 | 70-500 | 100-700 | 100-700 | 180-1000 | 180-1000 | 200-1300 | 200-1300 | 300-2000 | 500-3000 | 800-5000 | 1000-8000 |

| Mill drive (kW) | 3.3-4.0 | 10 | 10-15 | 12.5-17.5 | 17.5-24 | 17.5-24 | 24-30 | 24-30 | 36-45 | 36-45 | 36-58 | 36-58 | 55-75 | 55-84 | 70-110 | 160-250 |

| Cooling water throughput (L/h) | 250-400 | 800-1000 | 800-2000 | 800-2000 | 800-1500 | 800-1500 | 800-1500 | 800-1500 | 1800-2500 | 1800-2500 | 1800-2500 | 1800-2500 | 2000-4000 | 2000-4000 | 2000-5000 | 2000-6000 |

| Weight (kg) | 95-125 | 250-300 | 800 | 850 | 700 | 700 | 850 | 850 | 1600 | 1600 | 1800 | 1800 | 2500 | 3000 | 3200 | 8000 |

| Dimension L x W x H (mm) | 680 x 740 x 580 | 101 x 797 x 654 | 1300 x 1025 x 1385 | 1412 x 1025 x 1385 | 1500 x 882 x 1515 | 1515 x 882 x 1515 | 1740 x 882 x 1515 | 1754 x 882 x 1515 | 2030 x 1210 x 1780 | 2060 x 1210 x 1780 | 2205 x 1210 x 1780 | 2235 x 1210 x 1780 | 2900 x 1360 x 2130 | 3100 x 1360 x 2160 | 3270 x 1360 x 2130 | 3900 x 2495 x 2018 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.