Highest precision for ink

Our application areas have a fascinating variety

Flexo printing

The use of our agitator bead mills is a decisive step in the production of high-quality printing inks, which are specially developed for the flexographic printing process. This process of breaking down pigments, binders and other components in a liquid enables the production of high-quality printing inks. This also achieves outstanding print quality in the packaging and label printing industry.

Ceramics

The use of our agitator bead mills is a decisive step in the production of high-quality ceramic paints or pastes with high adhesion and resistance. The abrasive materials place high demands on the geometry and the materials installed in the machines. Dispersion and comminution open up new possibilities for creative design and individual decoration in the ceramic industry.

Offset printing

The use of our agitator bead mills is a fundamental step to produce high quality printing inks or inks specifically designed for the offset printing process. This processof breaking down and dispersing pigments, binders and other components in a liquid plays a key role in achieving accurate color reproduction and high quality in printed materials.

Rotogravure

The use of our agitator bead mills in rotogravure printing is a key step in producing high quality inks or inks with better adhesion and durability through uniform particle distribution. This process plays an important role in the production of environmentally friendly printed materials with high quality and precision e.g. high quality packaging, labels, magazines, catalogs, etc.

Screen printing

The use of our agitator bead mills in screen printing is a significant step towards producing high-quality inks thanks to uniform particle distribution. This process enables the creation of diverse print products such as textile printing, graphic design, arts and crafts with high quality and creative design.

Textile

The use of our agitator bead mills in textile printing is an important step in producing high-quality color pastes or inks specifically designed for printing on textiles. This process results in uniform particle distribution. As a result, the high-quality color pastes or inks have better adhesion on textiles and are durable and wash-resistant after printing.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our comprehensive portfolio is sure to contain the ideal model for your most demanding product.

Laboratory Agitator Bead Mill

DYNO-MILL UNI LAB

The laboratory agitator bead mill enables the use of DYNO-MILL UBM and ECM-AP technology and is ideal for R&D

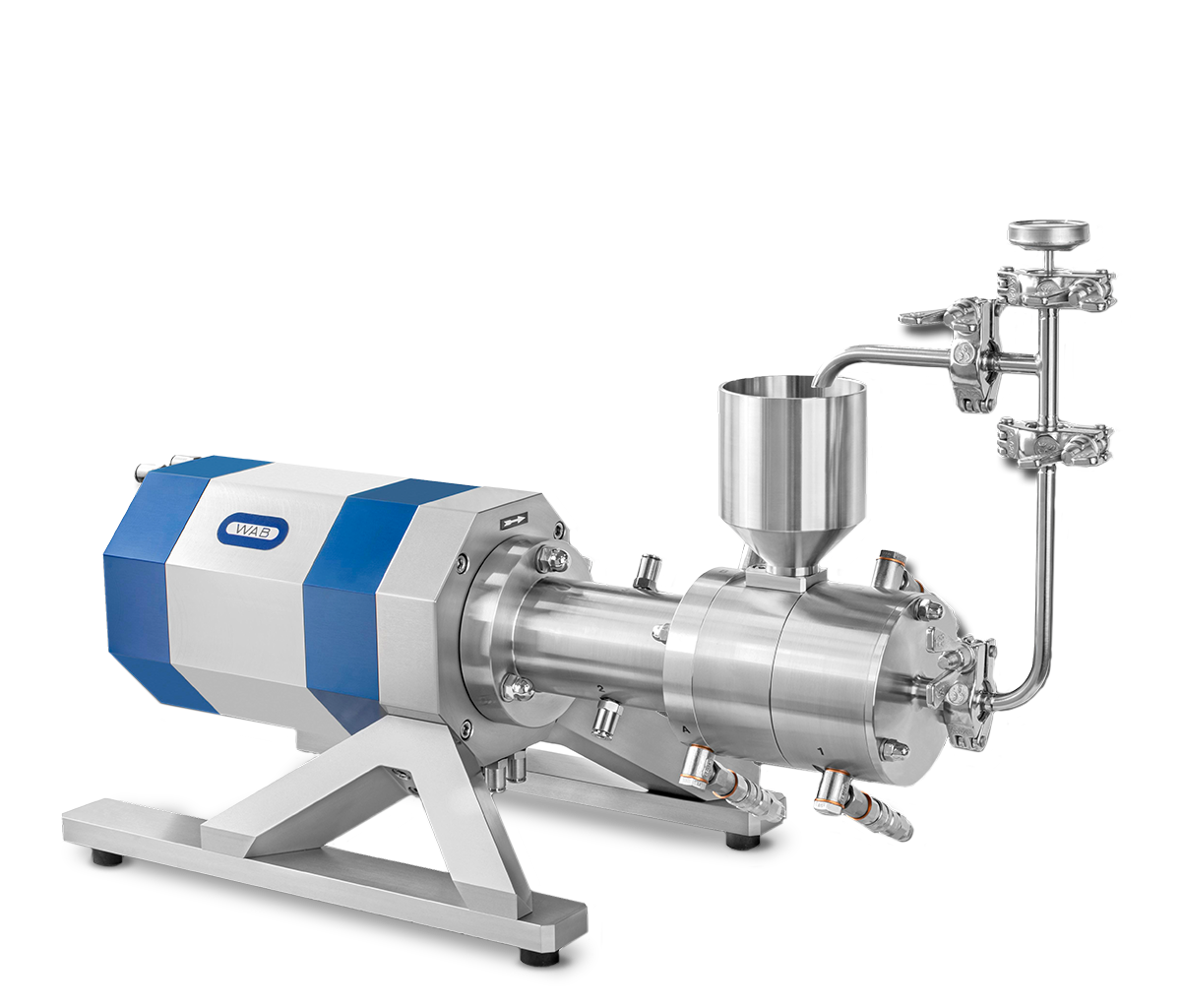

Universal Agitator Bead Mill

DYNO-MILL UBM

Efficient dispersion and fine grinding solutions for your products

Special Agitator Bead Mill

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Laboratory Agitator Bead Mill

DYNO-MILL MULTI LAB

The laboratory agitator bead mill is flexible in terms of grinding chamber size, material selection and grinding technology

Disc Agitator Bead Mill

DYNO-MILL KD

The mill is suitable for numerous applications and all types of grinding media materials

Laboratory Agitator Bead Mill

DYNO-MILL ECM-AP 05

The high-performance laboratory mill produces the finest and narrowest particle distributions down to the nanometer range

High-Performance Agitator Bead Mill

DYNO-MILL ECM-AP

The ideal agitator bead mill for high throughputs and highly viscous products

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.