Grinding and Dispersion Technology

Special Agitator Bead Mill

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Industries

Fast product development in miniature format

Our smallest agitator mill meets the special needs of research departments.

In the first syntheses, often only small quantities of product are produced. Realistic grinding tests can be a challenge. This is exactly where the DYNO-MILL RESEARCH LAB offers solutions: It delivers reproducible results from as little as 100 ml of suspension! The small mill is easy to dismantle and quick to clean - ideal for carrying out test series.

Functionality

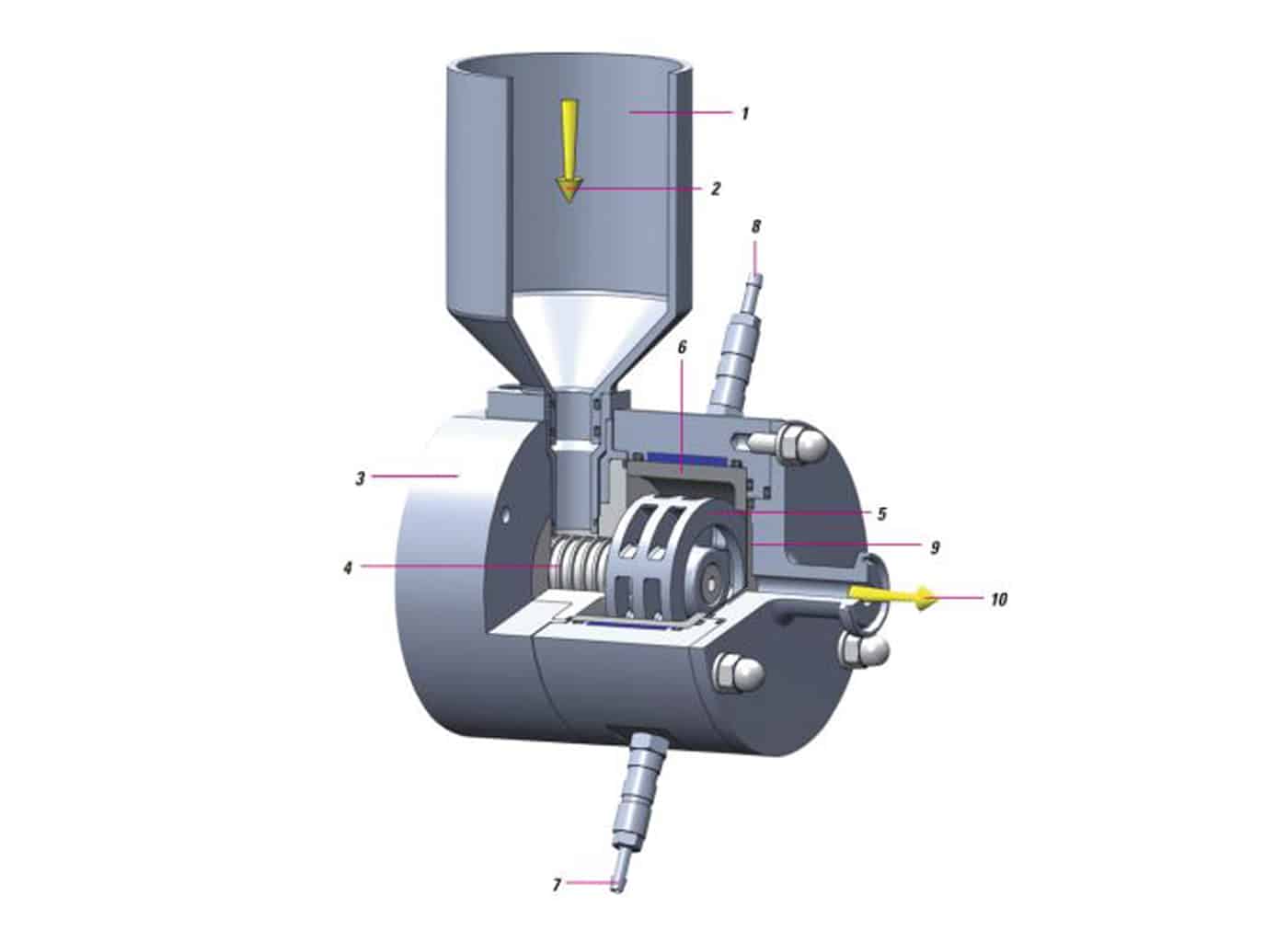

In the DYNO-MILL RESEARCH LAB, the suspension is fed into the grinding cylinder by a feed screw. The patented DYNO-ACCELERATOR accelerates the grinding media, ensures high energy input and guarantees efficient grinding of the particles - if necessary into the range of <100 nm. The grinding beads are retained in the mill by the sieve plate at the product outlet.

Separation system with self-cleaning effect

- Feed funnel 250 ml, 500 ml or 1000 ml

- Product inlet

- Seal housing for lip seal or double mechanical seal

- Feed screw

- DYNO-ACCELERATOR

- Coolable grinding container

- Cooling water inlet

- Cooling water outlet

- Grinding media separator - sieve plate with gap widths for the use of grinding beads ø 0.05-1.0 mm

- Product outlet

Features

The uniqueness of the DYNO-MILL RESEARCH LAB lies in its design: the entire grinding section can be separated from the drive by loosening just three screws. The dismantled grinding section can then be easily disassembled in a few simple steps. This means that cleaning work can be carried out quickly and conveniently. The separate grinding cylinder can be subjected to a sterilization process as a whole.

- Small product batches from 100 ml for processing in continuous passage and circulation mode

- Suitable for grinding media from ø 0.05-1.0 mm

- High energy input

- Particle finenesses < 100 nanometers

- Suitability for suspensions in the micron to nano range

- Ceramic design for metal-free processing

- Patented grinding principle with DYNO-ACCELERATOR

- Narrowest particle size distributions

- Easy-to-use control concept

- Production data acquisition (optionally available)

- Quiet operation with <65 dB(A)

- GMP-compliant design

Download

Find more information about our special agitator bead mill in compact form as PDF file. Rapid product development in miniature format.

Technical specifications

| Type | RESEARCH LAB |

|---|---|

| Grinding chamber volume (ml) | 80 |

| Minimum batch volume (ml) | 100 |

| Mill drive (kW) | 1.1 |

| Agitator shaft speed (rpm) | 1500-6000 |

| Cooling water throughput (L/h) | 100-300 |

| Weight of basic machine (kg) | approx. 25 |

| Dimension L x W x H (mm) | 620 x 250 x 430 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.