Individuality through inkjet

Our application areas have a fascinating variety

3D

The use of our agitator bead mills in 3D inkjet printing opens up an exciting future for additive manufacturing. Using finely ground raw materials, 3D inkjet printing can create extremely precise and detailed objects. This enables the use of different materials such as plastics, ceramics or metals in the production of complex geometric shapes, intricate structures and fine textures. Rapid prototype developments and small series production thus become economical.

Printer ink

The use of our agitator bead mills in the inkjet is a fundamental step to produce high quality printing inks or inks specifically designed for the inkjet process. This process of breaking down and dispersing pigments, binders and other ingredients in a liquid plays a key role in achieving accurate color reproduction and high quality in printed materials.

Nanography

The use of our agitator bead mills in nanography is extremely advanced and enables the production of high resolution inks and printing inks. Our solutions create nanoscale particles that are used in ink for inkjet printing to produce precise and controlled placement of ink droplets on the print media. This enables vibrant colors and high color brilliance on high-quality photo prints, packaging, labels, artwork, textile prints and more. Nanography offers maximum flexibility with the highest output.

Textile

The use of our agitator bead mills in textile inkjet printing opens up exciting possibilities for personalized textile manufacturing, the fashion sector, the home textiles market and other textile-related applications. Precise particle size control ensures even distribution of ink droplets on fabrics, resulting in color stability and wash resistance of textiles. Wet milling techniques enable the use of environmentally friendly inks that contain little or no measurable amount of harmful chemicals.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our comprehensive portfolio is sure to contain the ideal model for your most demanding product.

Laboratory Agitator Bead Mill

DYNO-MILL UNI LAB

The laboratory agitator bead mill enables the use of DYNO-MILL UBM and ECM-AP technology and is ideal for R&D

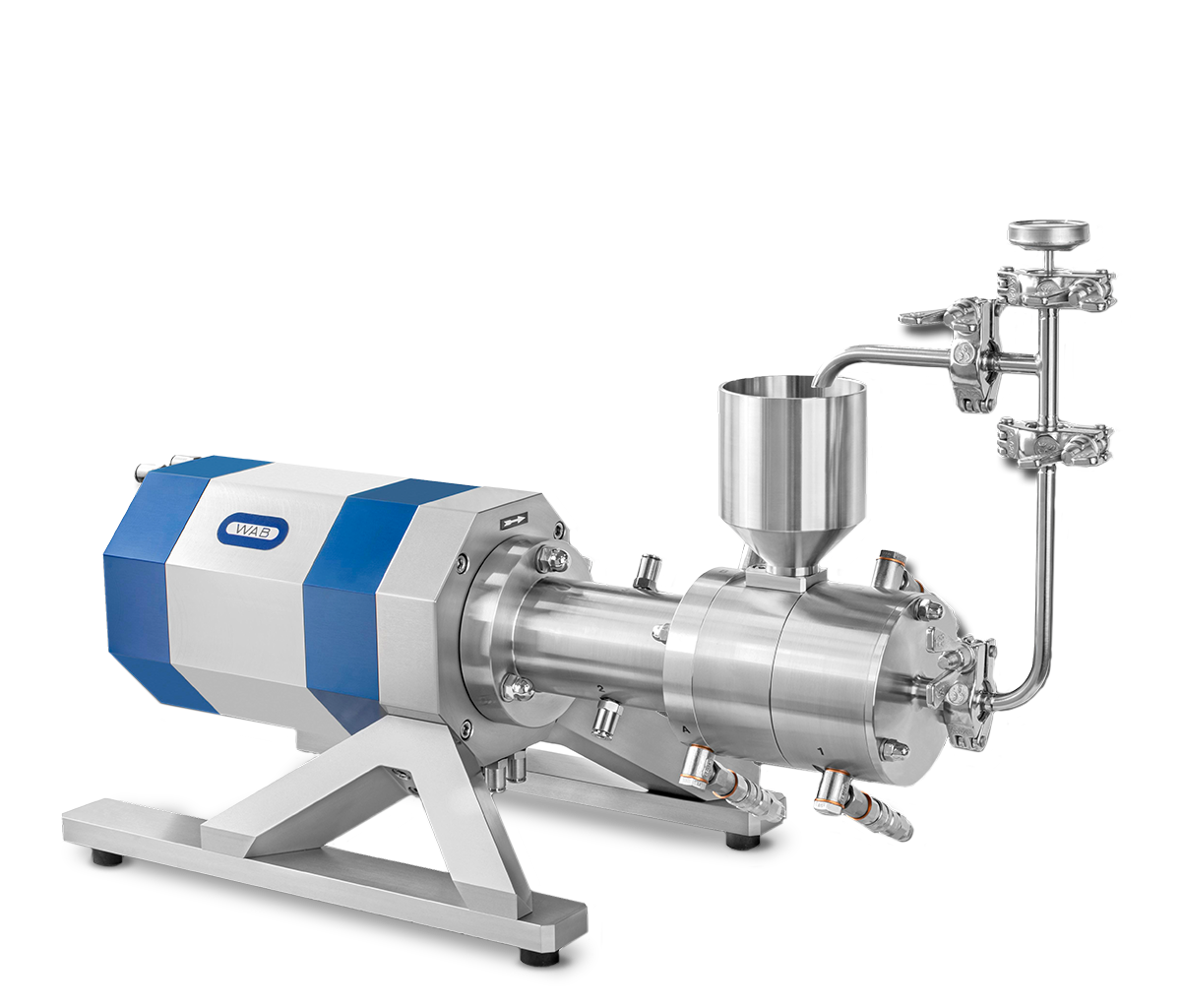

Universal Agitator Bead Mill

DYNO-MILL UBM

Efficient dispersion and fine grinding solutions for your products

Special Agitator Bead Mill

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Laboratory Agitator Bead Mill

DYNO-MILL MULTI LAB

The laboratory agitator bead mill is flexible in terms of grinding chamber size, material selection and grinding technology

Disc Agitator Bead Mill

DYNO-MILL KD

The mill is suitable for numerous applications and all types of grinding media materials

Laboratory Agitator Bead Mill

DYNO-MILL ECM-AP 05

The high-performance laboratory mill produces the finest and narrowest particle distributions down to the nanometer range

High-Performance Agitator Bead Mill

DYNO-MILL ECM-AP

The ideal agitator bead mill for high throughputs and highly viscous products

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.