Surface treatment

Our application areas have a fascinating variety

Glass materials

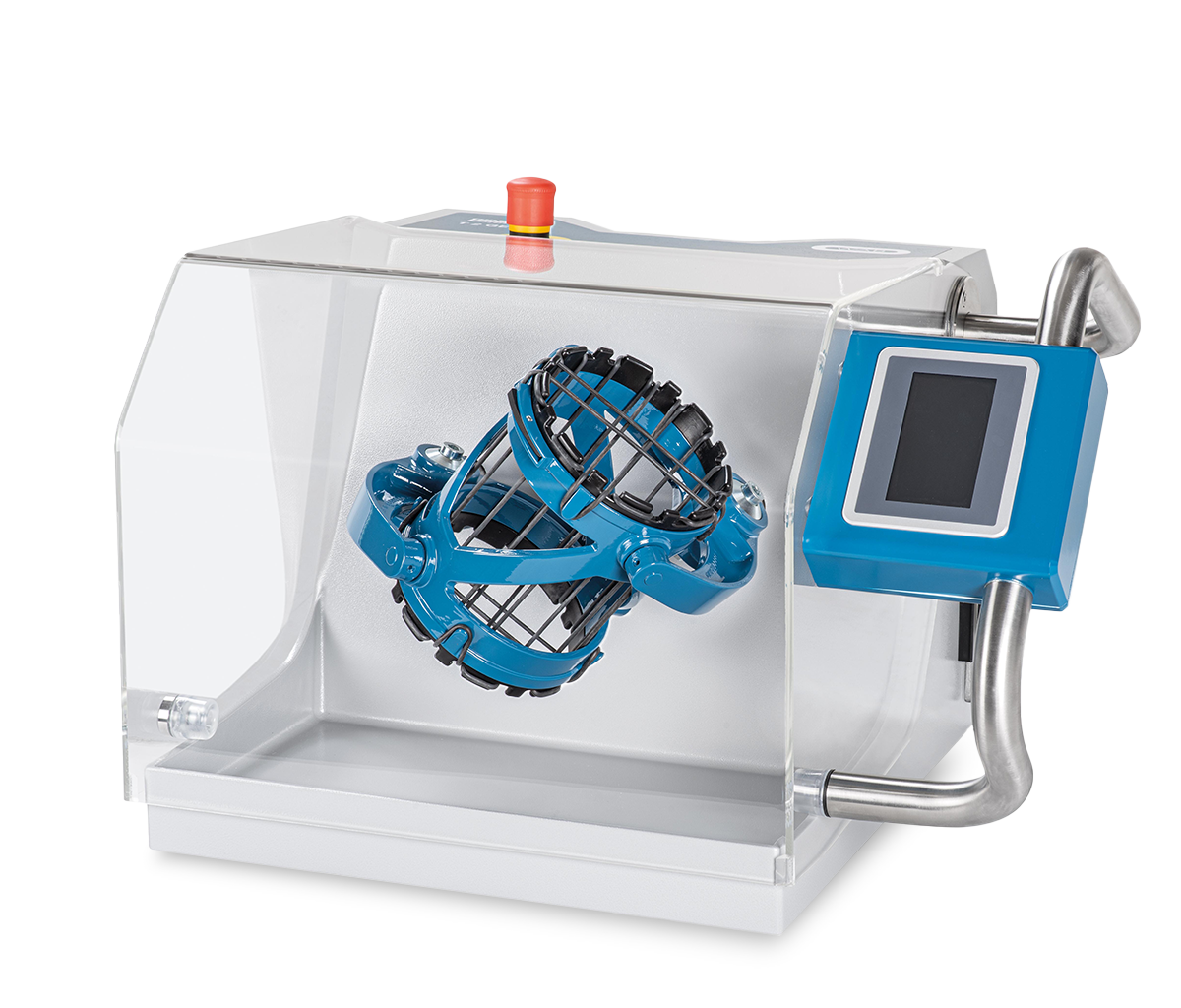

A perfect mixture is crucial to produce high-quality sintered glass materials. The quality of the final product depends strongly on the homogeneous distribution of the powders or particles in the starting material. Our three-dimensional shaker mixers guarantee the highest homogeneity in your mixture due to their unique movement.

Ceramic materials

A perfect mixture is crucial to produce high-quality sintered ceramic materials. The quality of the final product depends strongly on the homogeneous distribution of the powders or particles in the starting material. Our three-dimensional shaker mixers guarantee the highest homogeneity in your mixture due to their unique movement.

Magnetic materials

A perfect mixture is crucial to produce high-quality magnetic materials. The quality of the end product depends strongly on the homogeneous distribution of the powders or particles in the starting material. Our three-dimensional shaker mixers guarantee the highest homogeneity in your mixture due to their unique movement.

Polishing agent

Polishing agents are used to smooth, polish or clean surfaces. For this purpose, the surfaces to be polished and the polishing medium are processed in our 3D shaker mixer. The polishing medium consists of small particles or abrasives, such as abrasive particles made of plastic, ceramic or metal.

Technical materials

A perfect mixture is crucial to produce high-quality sintered engineering materials. The quality of the final product depends strongly on the homogeneous distribution of the powders or particles in the starting material. Our three-dimensional shaker mixers guarantee the highest homogeneity in your mixture due to their unique movement.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our application areas have a fascinating variety

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.