Response through innovation

Our application areas have a fascinating variety

Additives & Auxiliaries

In various industries such as food, chemistry, the plastics industry and many others, additives and auxiliary substances are used to improve certain properties or functions of products. These can include colorants, preservatives, thickeners, stabilizers and a variety of other substances. Our 3D shaker mixers ensure that additives and auxiliaries are homogeneously incorporated into a mixture. In this way, we guarantee the desired properties and functions of the end product.

Biodiesel

The use of our innovative WAB IMPA°CT REACTOR in the production of biodiesel marks a significant advance for the bioenergy industry. Our technology not only realizes energy savings in this novel production process, but also enables significantly higher production throughput. Our WAB IMPA°CT REACTOR uses kinetic energy and precise reaction control to ensure extremely efficient conversion of feedstocks. The resulting acceleration of the reaction rate leads to shortened reaction times and helps to reduce energy consumption during the manufacturing process.

Cellulose extraction

Our innovative WAB IMPA°CT REACTOR embodies the perfect symbiosis between chemical and mechanical separation of cellulose fibers. This unique combination sets a new standard in pulping and processing technology.The fractionation of Lignocellulose is an important process in biochemistry and biotechnology, in which Lignocellulose, the main component of plant biomass, is divided into its main components: Lignin, Hemicellulose and Cellulose. This fractionation enables the targeted further processing of these components into a wide range of chemical products and molecules with broad application in various industries.

Furfural

The integration of our WAB IMPA°CT REACTOR in the furfural production from hemicellulose not only simplifies the production process, but also contributes to the sustainable use of biomass. This technology makes it possible to produce valuable chemical products in an efficient and environmentally friendly way.

Catalysts

Our WAB IMPA°CT REACTOR opens up a novel method for the functionalization of heterogeneous catalysts. Its unique technology enables targeted reactions on the support surface, releasing unprecedented levels of performance. By precisely controlling reaction conditions, specific functional groups or structures can be created to maximize catalyst selectivity and efficiency.

Adhesives

Adhesives are substances used to bond materials together. They can occur in various forms and consistencies, including liquid or gel-like forms. Our 3D shaker mixers can be used in adhesive production to homogenize the components of adhesives, promote chemical reactions, and uniformly mix additives and fillers.

Plastics

Various types of raw materials are used in the plastics industry. These can be in the form of granules, powders, flakes or other particles. Our 3D shaker mixers homogenize these different components. This ensures a constant material and color with consistent quality.

Metal powder

Metal powders make it possible to produce materials with targeted properties, whether in terms of strength, conductivity, hardness or even color. The quality of the end product depends strongly on the homogeneous distribution of the powders or particles in the starting material. Our 3D shaker mixers guarantee the highest homogeneity due to their unique movement.

O-rings

O-rings can be individually coated. This is done using solid or liquid substances. The decisive factor is that a small amount of these substances must be uniformly applied to a large number of O-rings. These special coatings provide protection against aggressive UV radiation, chemicals, temperature fluctuations and abrasion. Our 3D shaker mixers provide the efficient solution.

Radioactive substances

The use of our 3D shaker mixers in combination with radioactive substances is a challenging and at the same time extremely significant field. This technology provides a precise and controlled method for mixing and handling radioactive materials in research, medicine, industry but also in waste processing.

Synthesis components

The manufacturing process of Solketal is based on the formation of a ketal ring between acetone and glycerol. This process takes place under acidic conditions. By using our WAB IMPA°CT REACTOR the reaction can be additionally accelerated, carried out in a continuous process and a higher yield of Solketal can be achieved.

Cement

The innovative mixing technology of our 3D shaker mixers offers an efficient and precise method to achieve the necessary additives to be mixed in. This uniformity is essential to ensure the quality and strength of the final product.

Additives for vulcanization

Zinc monoglycerinate is used as an additive for the vulcanization of rubber and in the plastics industry. The WAB IMPA°CT REACTOR enables a high reaction temperature and is predestined for the the production of ZnG.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our comprehensive portfolio is sure to contain the ideal model for your most demanding product.

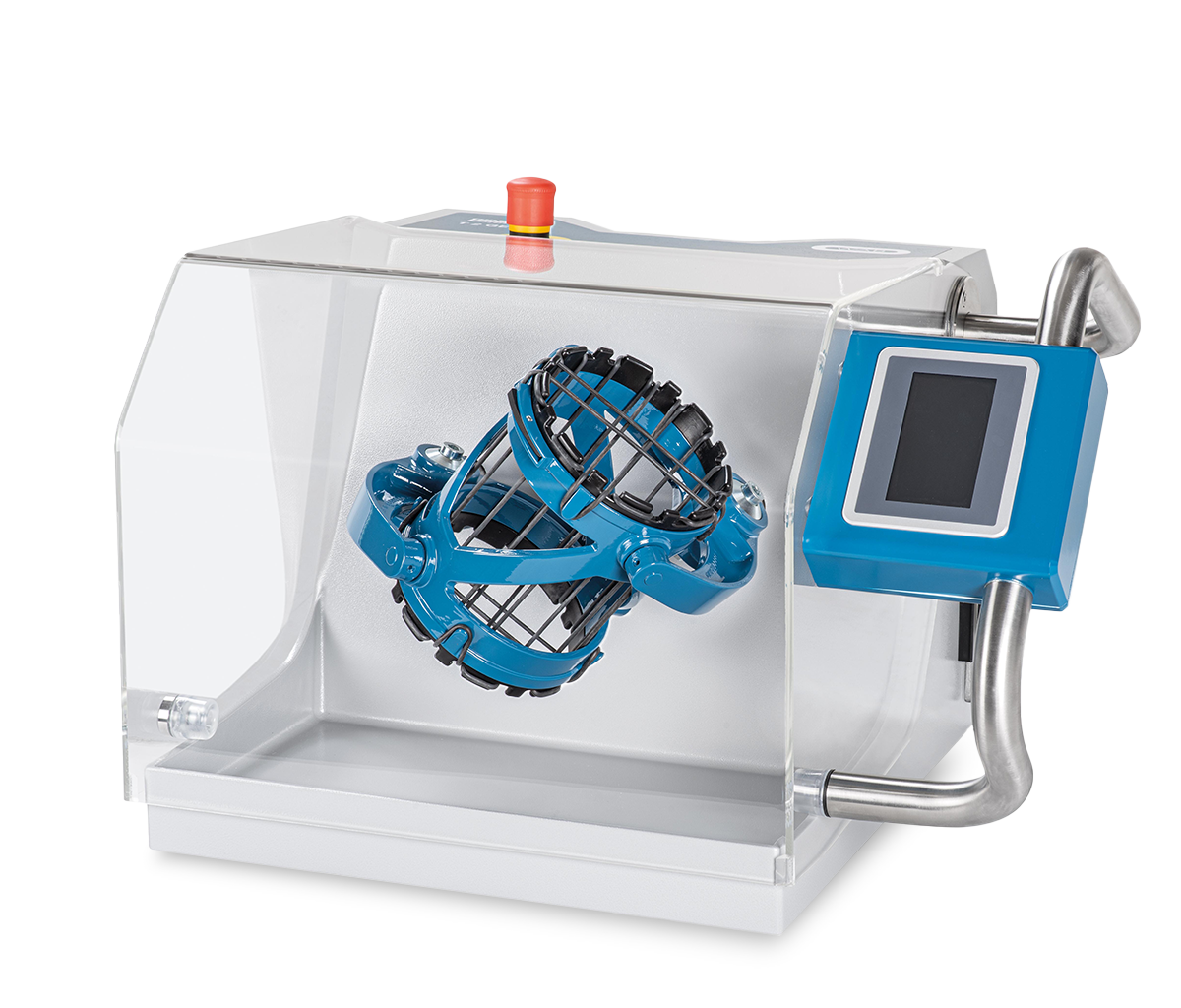

Mechanochemical reactor

WAB IMPA°CT REACTOR

An inductively heated mechanochemical reactor for continuous mechanochemistry

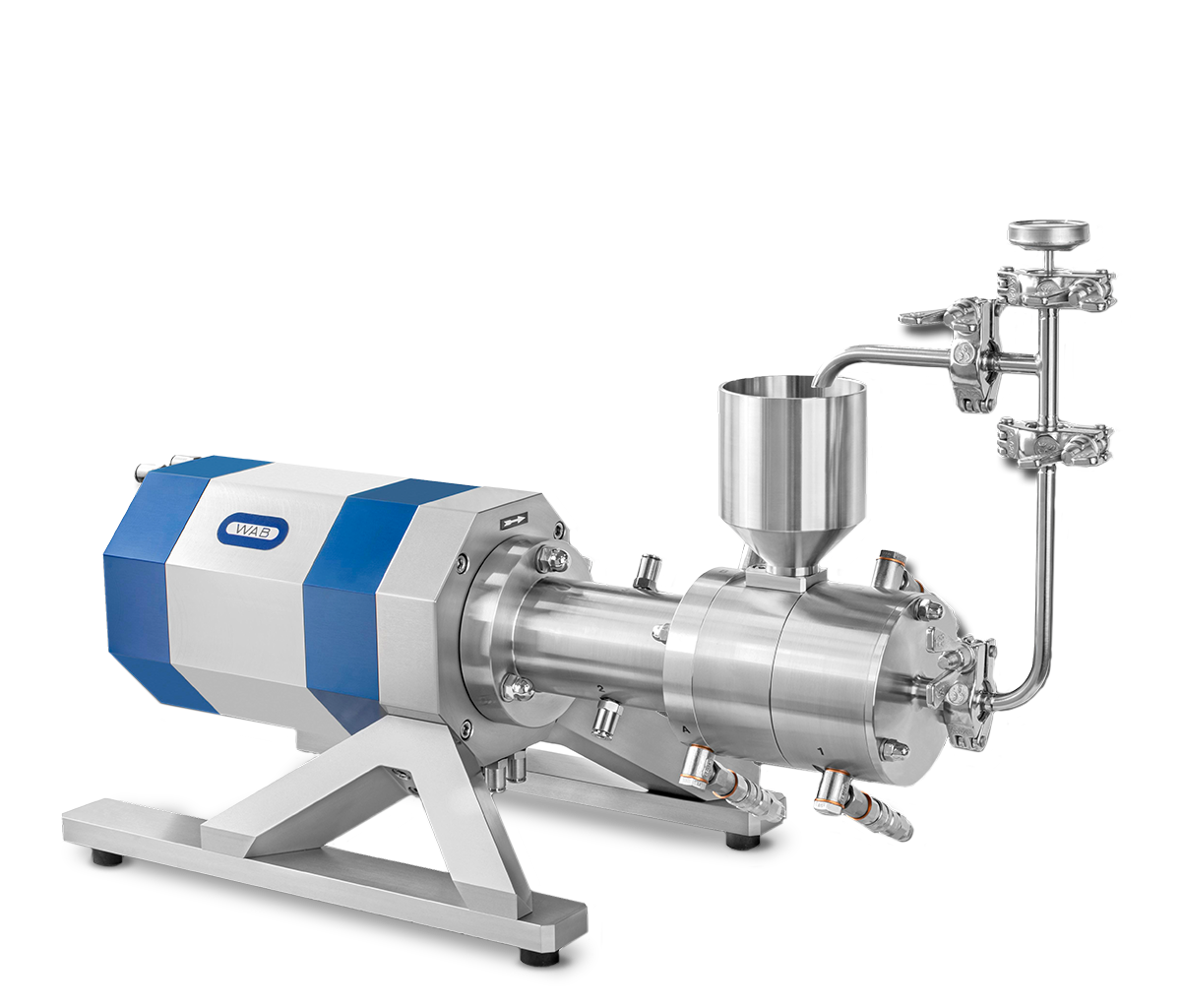

Special Agitator Bead Mill

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.