Flow Chemistry

Mechanochemical reactor

WAB IMPA°CT REACTOR

An inductively heated mechanochemical reactor for continuous mechanochemistry

A reliable solution for your process

The WAB IMPA°CT REACTOR is our latest innovation in the field of flow chemistry. An induction heater arranged around the stirring elements heats the reactants directly and efficiently up to +160 °C.

Conventional batch processes can be replaced by a continuous process. The WAB IMPA°CT REACTOR is a breakthrough, user-friendly and application-specific apparatus for molecular synthesis by mechanochemistry. It enables faster, more selective as well as novel reactivities and scale-up from g/h up to t/h.

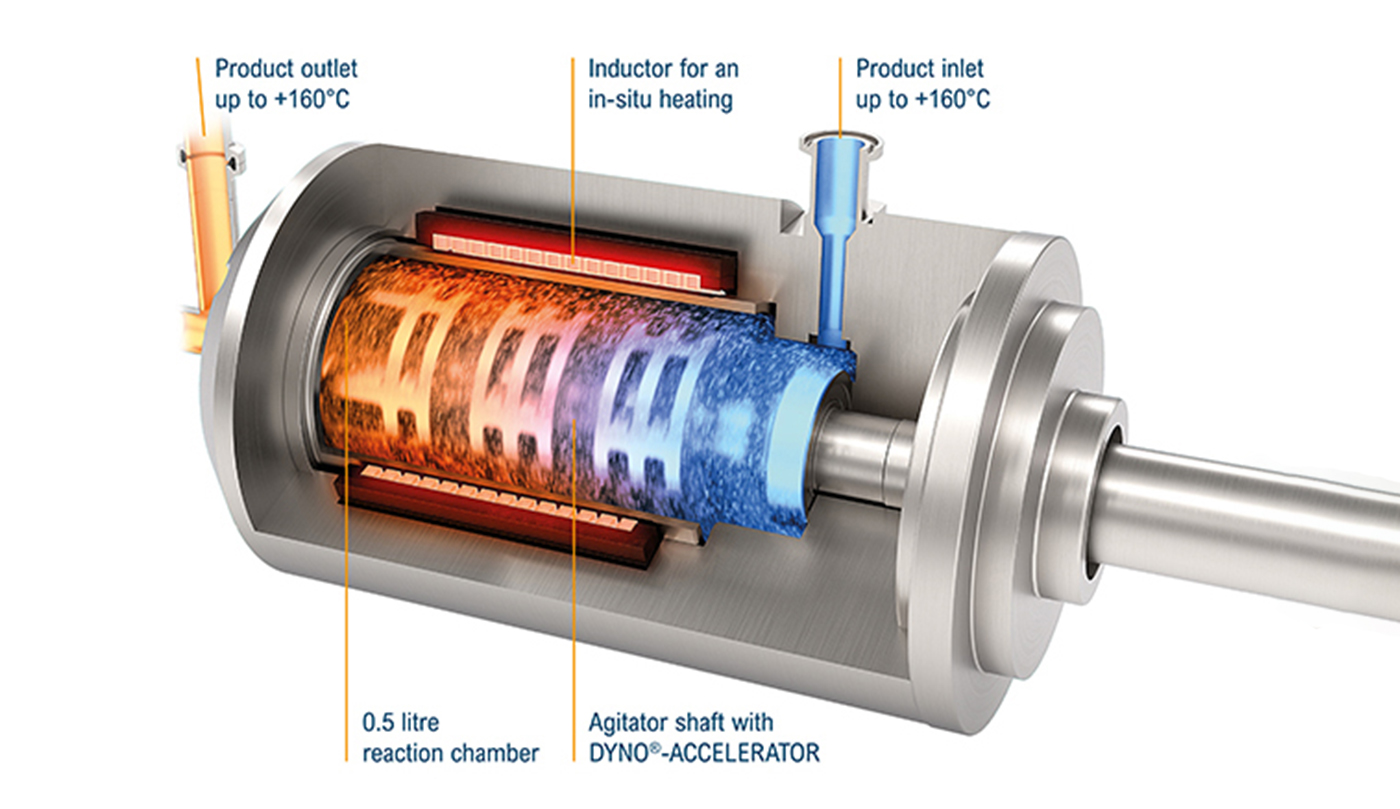

Functionality

The WAB IMPA°CT REACTOR with a horizontal reaction chamber is ideal for effective mass transfer and efficient activation of a chemical reaction. It can be used for liquid as well as viscous, pumpable products and heterogeneous catalysts and combines the three impact technologies in one reactor:

- the DYNO-ACCELERATOR

- the patented DYNO-DISC BC agitator discs

- the DYNO-DISC KD agitator discs

Together with the grinding media in the reactor chamber, this technology guarantees a high and uniform mechanical energy input and surface renewal of the reactants. In addition to endothermic processes, the mechanochemical reactor can also be used for exothermic reactions due to its excellent cooling properties.

Advantages at a glance

Reduction of carbon footprint

- Reduction of energy use

Cost reduction by process intensification

- Mass transport improvement

- Reduction of the amount of solvents and reagents

- Increase selectivity and yield

Cost competitive equipment in terms of CAPEX and OPEX

- Reduction in the number of process steps

- Positive ROI effects

Technical leverage by a new approach

- Bring to temperature locally

- Mechanical and inductive heating

- New molecules and functions

- New synthesis routes

Application examples

Synthesis of solketal

Solketal is a synthesis building block in the chemical and pharmaceutical industry and can be produced on the WAB IMPA°CT REACTOR.

Synthesis of zinc monoglycerinate (ZnG)

Zinc monoglycerolate is used as an additive for the vulcanization of rubber and in the plastics industry. The WAB IMPA°CT REACTOR enables a high reaction temperature and is predestined for the production of ZnG.

Download

Find more information on our mechanochemical reactors in compact form as a PDF file. A reliable solution for your process.

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.