Versatile beauty care

Our application areas have a fascinating variety

Basic molecules

The use of biomass instead of petroleum in the cosmetics industry is an increasing trend in the quest for sustainable and environmentally friendly products. Flow Chemistry enables a continuous flow of product and a residence time tailored to the product within the WAB IMPA°CT REACTOR. Excellent surface renewal enables particularly efficient activation of reactants and catalysts, which in turn reduces the total energy requirement.

Cream

The use of nanoparticles increases the effectiveness of the solid in creams. The formulation becomes mostly transparent, thus reducing whiteness during application, facilitating application to the skin and offering a broader spectrum of protection against the various UV rays, especially in sun creams. The use of our advanced agitator bead mills allows for continuous development and improvement of the properties and efficacy of creams and skin care products.

Dyes

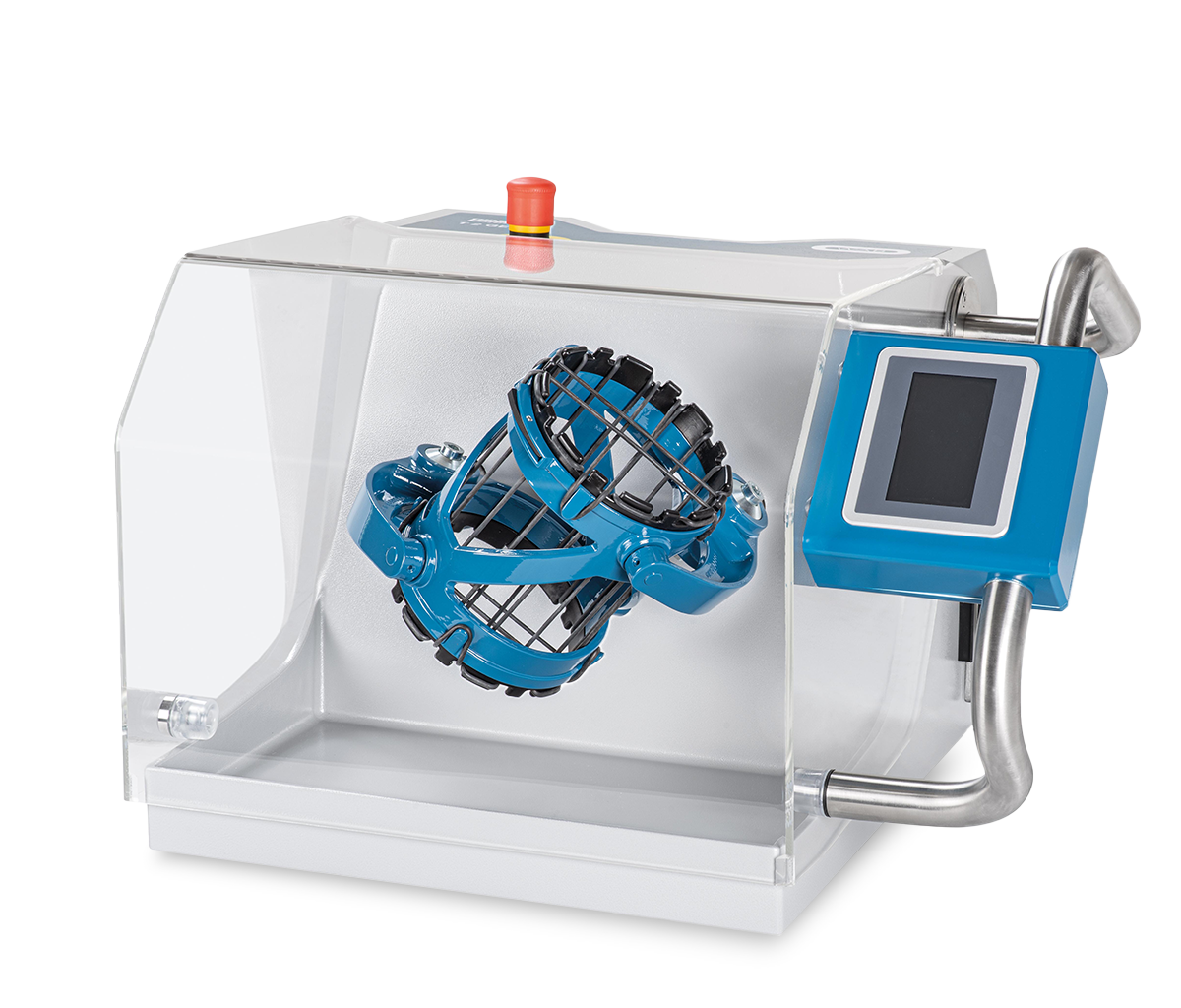

In cosmetics, dyes and pigments are used to add color to products. With our 3D shaker mixers, we ensure that the dyes and pigments are evenly distributed. A homogeneous coloration, color intensity and color consistency are thus achieved. This is important to ensure that the end products meet quality standards.

Skin/Sun Protection

Skin and sunscreens containing nanoparticle titanium dioxide are an advanced type of sunscreen product. Titanium dioxide is a mineral active ingredient used in sunscreen and lotions to protect the skin from harmful UV rays. In nanoparticle form, titanium dioxide is broken down in such a way that the particle size is in the nanometer range. Our agitator bead mills offer you the most efficient and reliable way.

Injectables in cosmetic surgery

In cosmetic surgery, the exact composition of injectables is crucial for optimal results. Here, our 3D shaker mixers set new standards: Their three-dimensional movement ensures homogeneous distribution of active ingredients such as hyaluronic acid or botulinum toxin with the fillers. This ensures not only reproducible mixing results, but also compliance with GMP specifications in the pharmaceutical industry.

Lipstick

Our agitator bead mills are a key technology used in the cosmetics industry for the production of lipsticks. In this process, pigments are dispersed in a liquid phase and comminuted. This is of decisive importance to achieve the desired color strength and opacity with minimum raw material and energy consumption.

Minerals

Minerals have become an unstoppable trend in cosmetics, as they not only deliver glamorous color, but also offer skin-care benefits. From flawless foundations to shimmering eye shadow, mineral-based products offer a natural alternative. It is all the more important that these valuable minerals are homogeneously distributed in the formulations. This ensures consistent quality for the user. With our 3D shaker mixers, this is guaranteed.

Nail polish

Modern nail polishes are usually composed of two components: the gel and the pigmented colour paste. When the gel is ground, the focus is on the flow properties and gloss. With the separately milled color paste, the main focus is on the coloristic properties such as color strength, color location and gloss. In combination of all properties, the gel base and the color paste complement each other to form a ready-to-use nail polish. We offer the entire range of agitator bead mills for the production of high-quality gels and color pastes.

Mascara

Mascara is a cosmetic product used to make eyelashes appear darker, longer and more voluminous.The solid ingredients, such as pigments and fibers, are wet-milled and dispersed in the liquid, avoiding the formation of lumps and achieving an even pigment distribution and texture. Our agitator bead mills help to achieve the desired consistency, color intensity and quality of the mascara and thus meet the highest customer expectations.

Additives

Our 3D shaker mixers are used in the cosmetics industry for efficient and precise mixing of additives in cosmetic products. From moisturizing hyaluronic acids to revitalizing vitamins and protective antioxidants, these additives help increase the effectiveness of cosmetic products. The three-dimensional mixing motion blends cosmetic formulations and additives in a highly homogeneous manner.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our comprehensive portfolio is sure to contain the ideal model for your most demanding product.

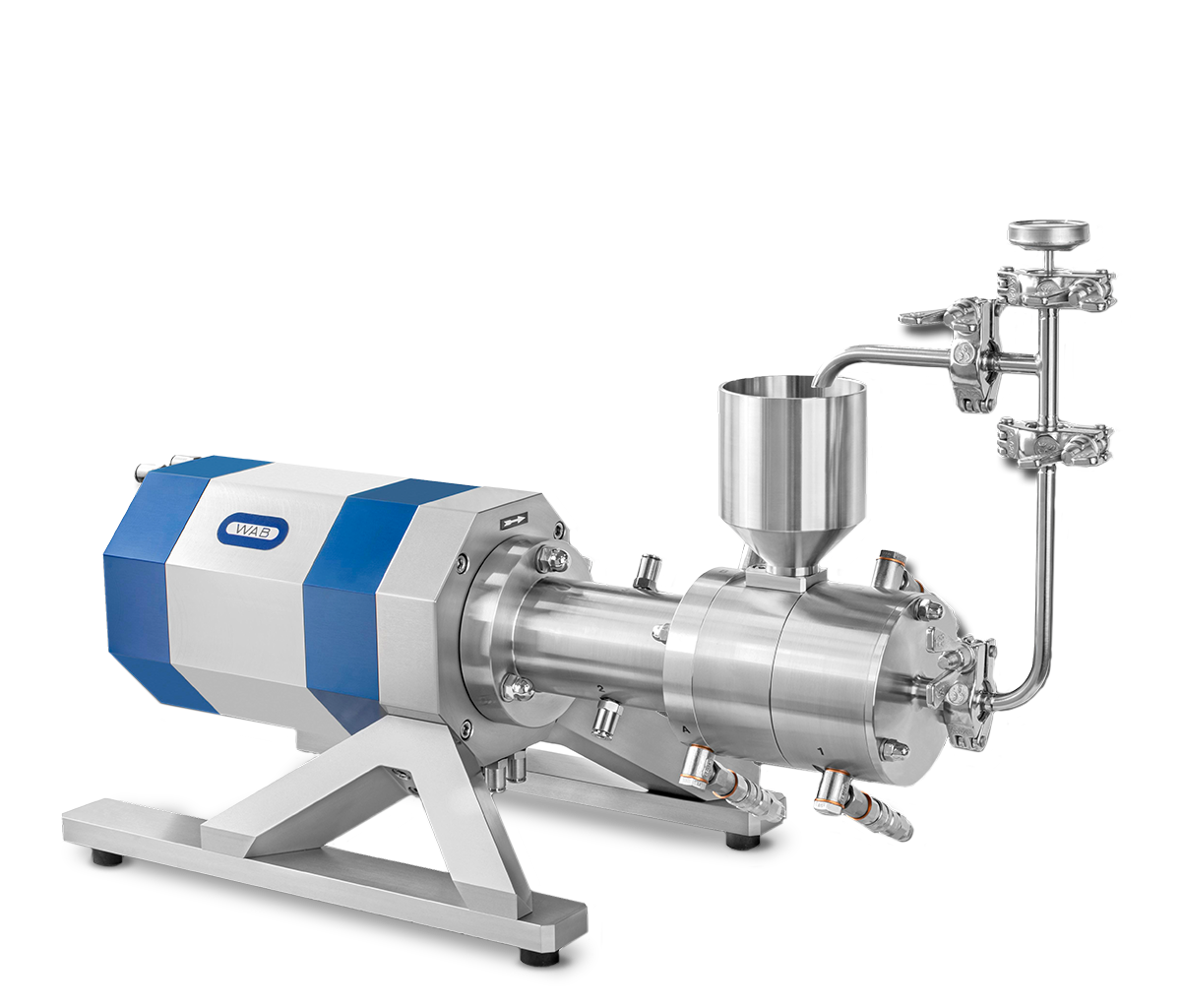

Mechanochemical reactor

WAB IMPA°CT REACTOR

An inductively heated mechanochemical reactor for continuous mechanochemistry

Laboratory Agitator Bead Mill

DYNO-MILL UNI LAB

The laboratory agitator bead mill enables the use of DYNO-MILL UBM and ECM-AP technology and is ideal for R&D

Universal Agitator Bead Mill

DYNO-MILL UBM

Efficient dispersion and fine grinding solutions for your products

Special Agitator Bead Mill

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Laboratory Agitator Bead Mill

DYNO-MILL MULTI LAB

The laboratory agitator bead mill is flexible in terms of grinding chamber size, material selection and grinding technology

Disc Agitator Bead Mill

DYNO-MILL KD

The mill is suitable for numerous applications and all types of grinding media materials

Laboratory Agitator Bead Mill

DYNO-MILL ECM-AP 05

The high-performance laboratory mill produces the finest and narrowest particle distributions down to the nanometer range

High-Performance Agitator Bead Mill

DYNO-MILL ECM-AP

The ideal agitator bead mill for high throughputs and highly viscous products

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.