Groundbreaking technologies for your surface engineering

Our application areas have a fascinating variety

Automotive painting

Wet grinding technology plays a decisive role in meeting the high demands and customer requirements in automotive paint production. It enables the production of coatings that are not only aesthetically pleasing, but also meet the high technical standards required for automotive painting.

Whether clear coat, base coat, filler or primer - using our agitator bead mills, you can efficiently achieve fine particle sizes and particle distributions - for brilliant colors, long-lasting gloss and flawless adhesion, as well as scratch resistance for the ultimate vehicle aesthetics.

Car refinishing

Coatings in automotive repair must offer color accuracy, fast drying and durability. Seamless integration, adhesion and environmental friendliness are also critical. Coatings compensate for surface irregularities and are chemical resistant to ensure long-term protection.

Our agitator bead mills help to ensure that coatings in automotive repair meet high quality standards and fulfill both aesthetic and functional requirements. The homogeneous distribution and grinding of the particles, makes efficient formulations and precise compositions possible in the first place.

Coil coating

Coil coating involves the application of coatings to rolled metal strips that are later processed into various products such as roof panels, facade cladding, household appliances and more. The coating materials must not only provide a visually appealing surface, but also offer resistance to corrosion, weathering and mechanical stresses.

Our agitator bead mills allow precise control of particle size and distribution of coating materials. Grinding and dispersing the materials enables uniform coating thickness and quality.

Wood varnish

This application is enormously exciting because wood, as a natural material, is used in every conceivable area of life. The requirements vary like hardly any other paint application: There are worlds between an exterior coating and a coating for children's toys!

An exterior coating must first and foremost protect the wood from the effects of weathering. In addition, aesthetic issues play an important role: Should the wood grain be completely covered or is a certain transparency desired?

By choosing the right grinding parameters, you can, for example, specifically control the gloss and transparency of the wood varnish. Depending on the choice of pigmentation, the particle distribution also increases UV resistance.

In the formulation of children's toy coatings, regulations drastically reduce the choice of ingredients. The focus is therefore on producing a paint that meets all legal requirements.

Ship painting

Marine coatings are specially formulated coatings used on ships and marine structures to protect them from corrosion, abrasion and impact, seawater, UV radiation, fresh and salt water, fuels and various chemicals, algae infestation, and temperature fluctuations.

In the marine coatings industry, wet grinding is used to incorporate pigments, fillers and other additives into liquid binders. This enables the production of coatings with uniform distribution of ingredients and optimized performance.

In addition to the chemical requirements, the surface properties are also important. For example, the surface structure of the coating has a major influence on the frictional resistance of the ship's surface when passing through water. Wet grinding to finer grain sizes can reduce frictional resistance - and lower the ship's energy consumption. It is therefore important that the surfaces remain as smooth as possible and free of algae and shellfish. This is achieved by adding antifouling additives.

Textile coating

Textiles are coated for various reasons to improve their aesthetic, functional and protective properties. Due to the homogeneous comminution and dispersing with our agitator bead mills down to the nano range, we enable an even distribution of the coating on the textile fibers.

Packaging coating

High-quality packaging coatings must meet a wide range of requirements: They protect against environmental influences, lend aesthetics, increase durability and optimize the presentation of the product. Whether corrosion protection, brand identity or functionality, our agitator bead mills play a central role in the elaboration of particle properties.

Powder coating

Grinding & Dispersion Technology

Powder coating is an important process in surface coating technology. This approach is used to achieve a uniform and high quality coating on various substrates. Our agitator bead mills enable better dispersion of powder particles, resulting in improved adhesion and tack to surfaces, smooth and uniform coatings, and different color and texture variations. Our agitator bead mills produce powder coatings with improved filling and flow properties, resulting in a more uniform, efficient coating and reduced dust generation.

Mixing Technology

Powder coating is a surface coating process in which a dry powder material is applied to a substrate. Our 3D shaker mixer is used to mix powders or granules homogeneously to achieve an even distribution of particles.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our comprehensive portfolio is sure to contain the ideal model for your most demanding product.

Laboratory Agitator Bead Mill

DYNO-MILL UNI LAB

The laboratory agitator bead mill enables the use of DYNO-MILL UBM and ECM-AP technology and is ideal for R&D

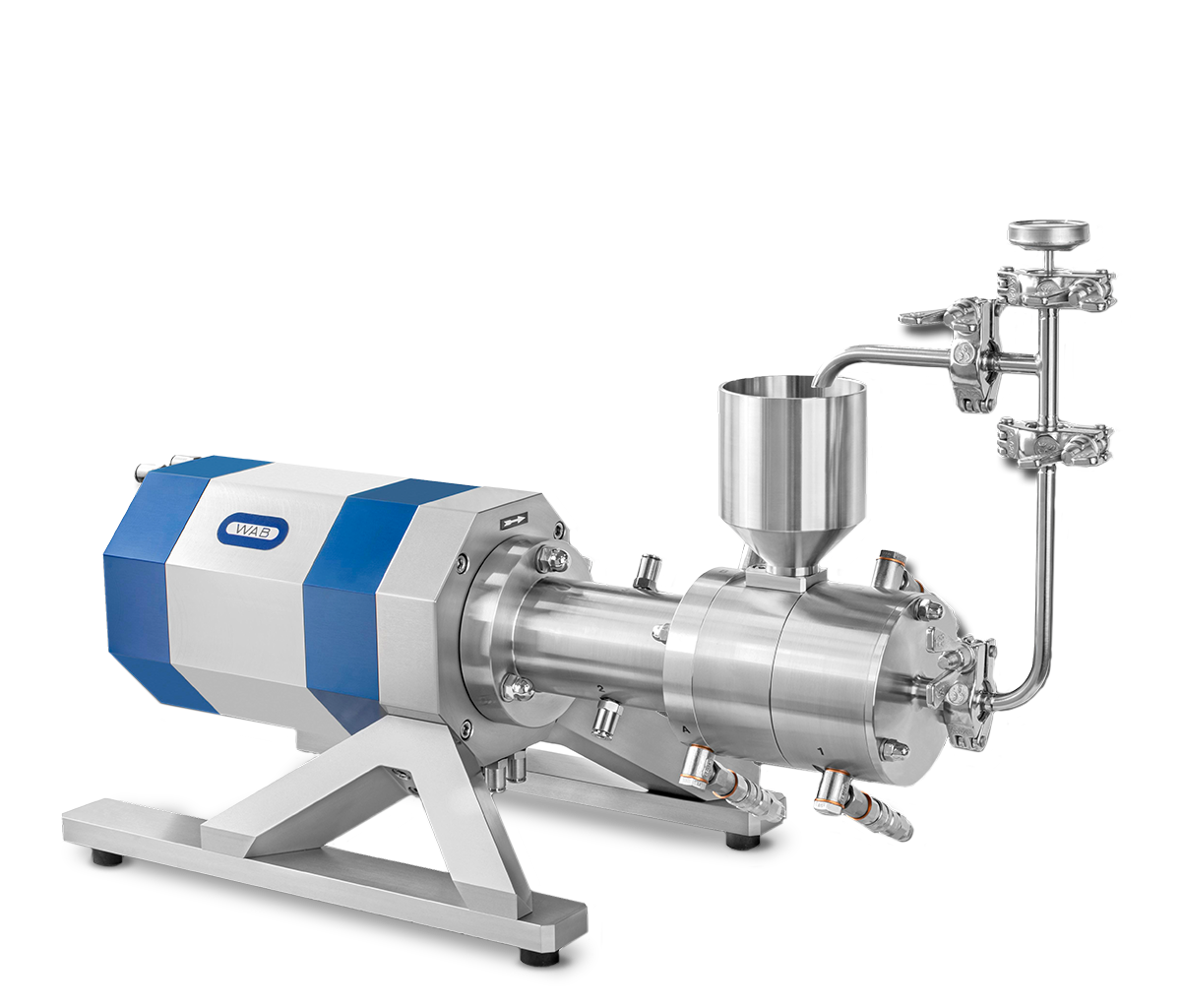

Universal Agitator Bead Mill

DYNO-MILL UBM

Efficient dispersion and fine grinding solutions for your products

Special Agitator Bead Mill

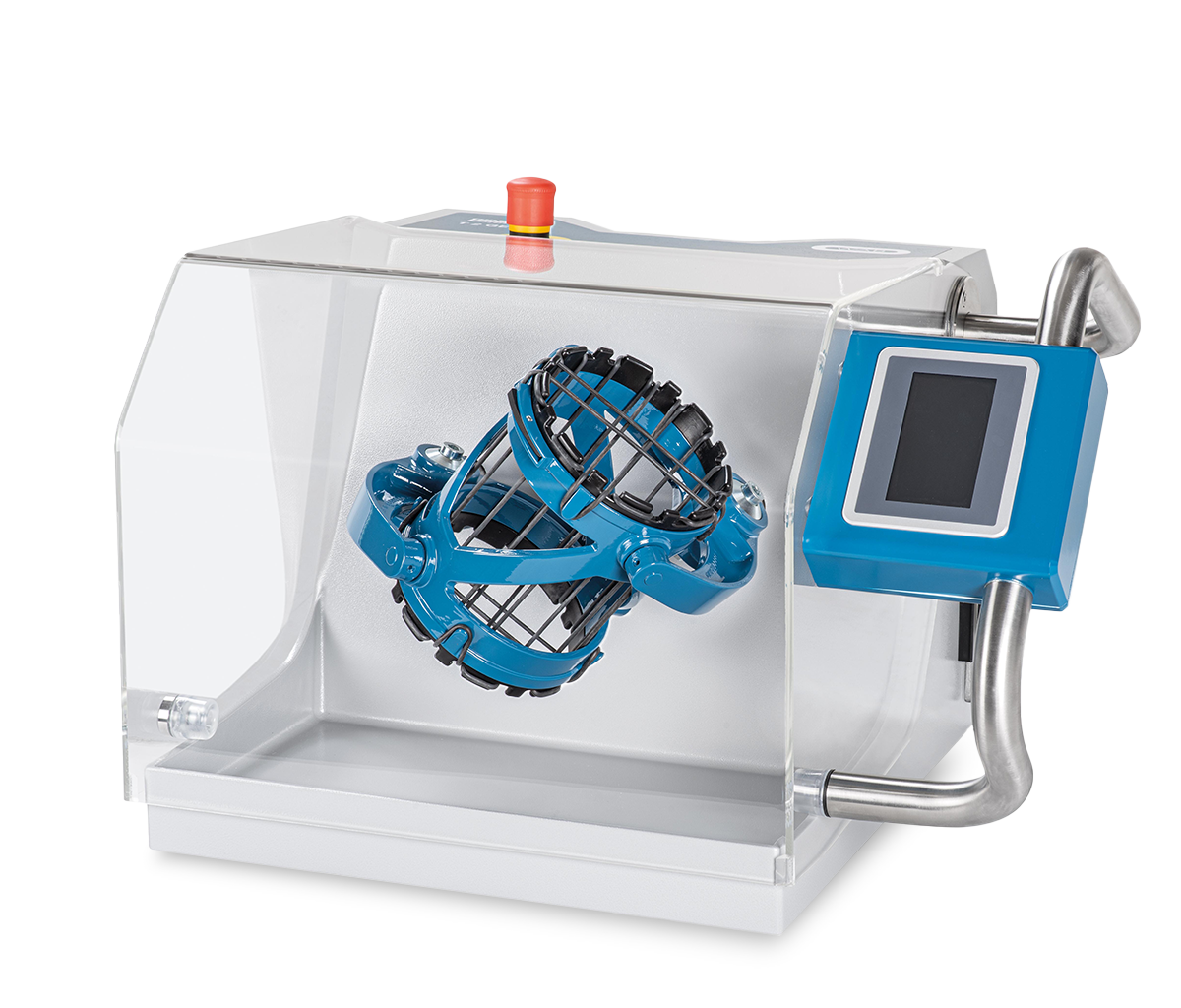

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Laboratory Agitator Bead Mill

DYNO-MILL MULTI LAB

The laboratory agitator bead mill is flexible in terms of grinding chamber size, material selection and grinding technology

Disc Agitator Bead Mill

DYNO-MILL KD

The mill is suitable for numerous applications and all types of grinding media materials

Laboratory Agitator Bead Mill

DYNO-MILL ECM-AP 05

The high-performance laboratory mill produces the finest and narrowest particle distributions down to the nanometer range

High-Performance Agitator Bead Mill

DYNO-MILL ECM-AP

The ideal agitator bead mill for high throughputs and highly viscous products

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.