More environmentally friendly alternative

To date, vanillin has largely been produced synthetically using petroleum-based raw materials that generate chemical waste. A more environmentally friendly alternative is vanillin production based on biomass-derived feedstock. The transformation of biomass into fuels and chemicals is becoming increasingly popular to mitigate the current global warming trend and diversify energy sources.

Mechanical force

This mechanochemical reaction benefits from the input of mechanical and thermal energy as well as pressure activation. It enables a novel approach to vanillin synthesis without the use of any catalytic system.

Faster reaction

By combining these unique properties, the synthesis in our DYNO-MILL MULTI LAB and DYNO-MILL RESEARCH LAB could be carried out in less time and at lower process temperatures.

Better quality

The combination of continuous flow and mechanochemistry led to excellent results in terms of conversion, selectivity and yield of vanillin. The results were achieved in a lab and pilot-scale machine.

Scalability

The use of a DYNO-MILL enables a continuousprocess compared to the discontinuous process of the conventional batch heating process. The main advantage of a continuous process is the possibility of scaling up to industrial scale, which means a completely new perspective for vanillin production.

Alternative to petroleum-based compounds

Although more than 12’000 tons of vanillin are produced per year, only less than 1% is natural vanillin, while the remainder is synthesized through chemical processes. This research using DYNO-MILL technology was conducted with chemicals derived from biomass feedstocks.

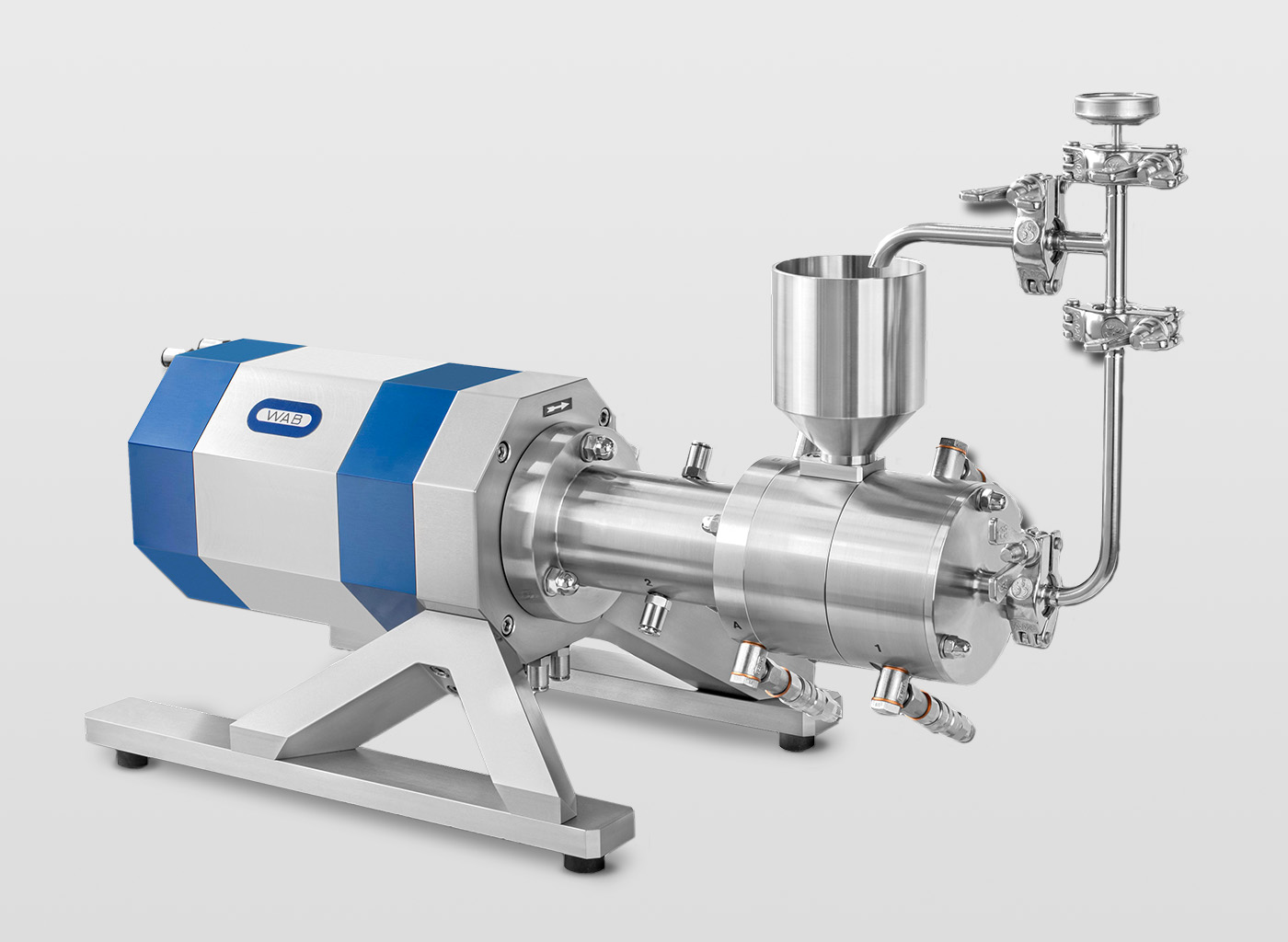

DYNO-MILL RESEARCH LAB

The solution for achieving reactions in flow chemistry with less solvent and lower energy consumption.

DYNO-MILL MULTI LAB

The solution for processing fibrous or liquid products in a mechanochemical reaction.

The research was led by Deasyl SA (Switzerland) and the Department of Organic Chemistry at the University of Córdoba.

https://pubs.acs.org/doi/10.1021/acs.iecr.3c02250

Contact Switzerland

Would you like information or advice on our products? Our team is at your disposal.

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.