Grinding and dispersion technology

Special Agitator Bead Mill

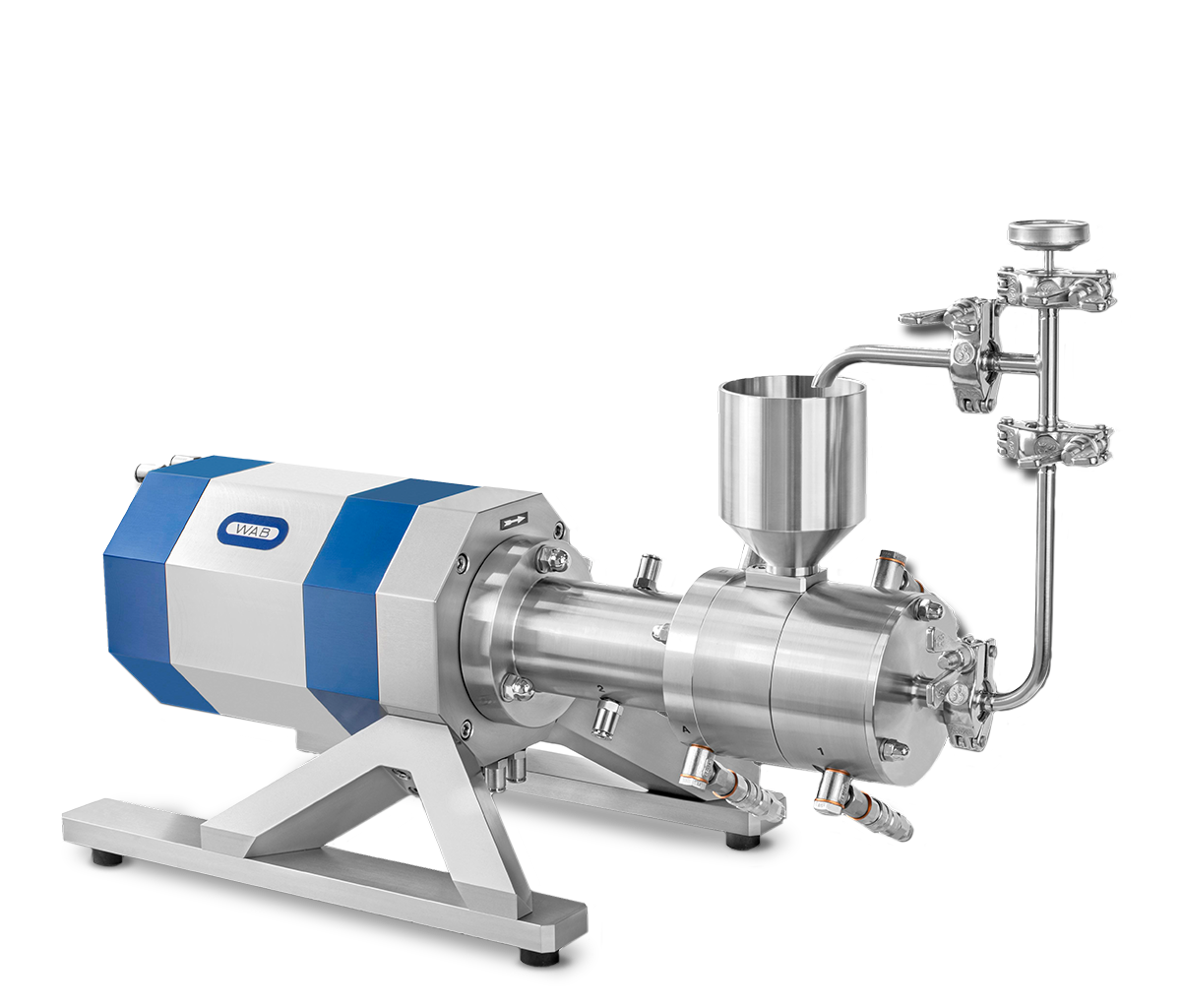

DYNO-MILL NPM

The special agitator bead mill for nanosuspensions

Industries

Ultrafine wet grinding and dispersing

The DYNO-MILL NPM (Nano Performance Mill) is used for continuous dispersion and wet grinding of thin to viscous products in the micron and nano range.

The unique grinding media separation system allows the use of very small grinding media 0.05 to 0.2 mm and the patented DYNO Accelerators ensure stable process operation even at highest throughputs.

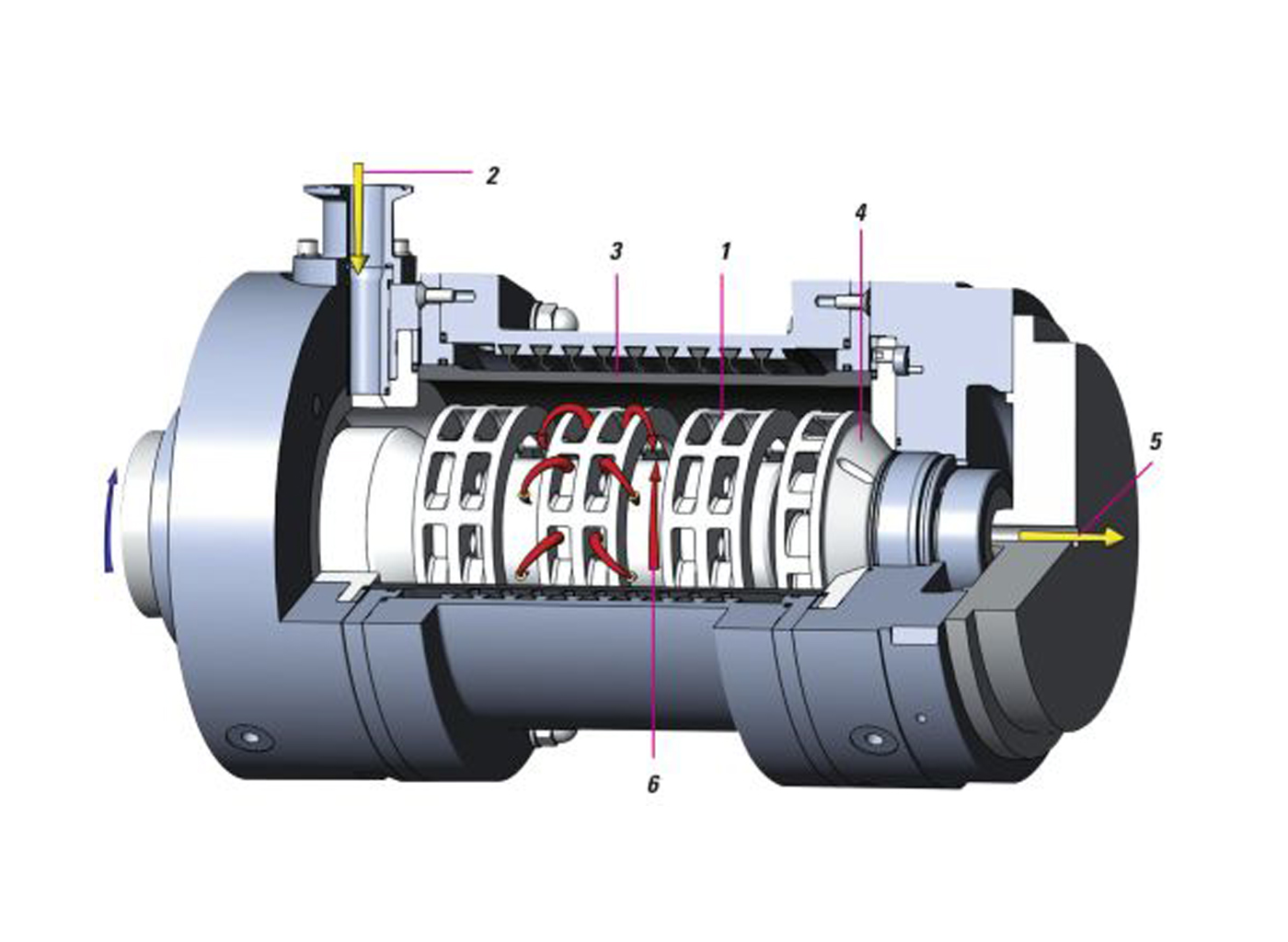

Functionality

The agitator bead mill has a dynamic, rotating grinding media separation system with its own drive. This enables process adjustment in two steps. The peripheral speed of the separation system ensures that the grinding media are safely separated from the material to be ground. The peripheral speed of the agitator shaft can be adjusted to the needs of the grinding task independently of the separation system.

With the unique, patented grinding principle, the DYNO-ACCELERATOR, the best product quality with the narrowest particle size distribution down to the fineness range of <100 nm is achieved. The DYNO-ACCELERATOR causes a powerful, hydraulic movement of the grinding media and guarantees a high and uniform energy input for low-viscosity to viscous products as well as gentle processing.

Dynamic grinding chamber system

- DYNO-ACCELERATOR

- Product inlet/grinding bead inlet

- Coolable grinding tank with grinding cylinder

- Dynamic separation system for use of grinding media with ø 0.05-0.2 mm

- Product outlet

- Grinding bead circulation

Features

- Suitable for passage and circuit operation with consistent efficiency and achievement of the narrowest particle size distributions

- Long service life and metal-free grinding due to the use of high-quality ceramics

- Low energy consumption thanks to efficient energy input

- Small process volume and ideal cooling properties allow processing of temperature-sensitive products

- Easy to operate, record operating data and ensure reproducibility

- Easy cleaning with little detergent

- Easy handling with low operating and maintenance costs

- Low-gap design of the grinding chamber

Download

Find more information about our special agitator bead mill in compact form as PDF file. Ultrafine wet grinding and dispersing.

Technical specifications

| Type | NPM Pilot |

|---|---|

| Grinding chamber volume (l) | 2,0 |

| Capacity range (l/h) | 10-100 |

| Mill drive (kW) | 7.5-11.0 |

| Separator drive (kW) | 2,0 |

| Grinding media Ø (mm) | 0.05-0.2 |

| Cooling water throughput (L/h) | 1000 |

| Weight (kg) | 900 |

| Dimension L x W x H (mm) | 1400 x 700 x 1700 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.