Battery materials of the future

Our application areas have a fascinating variety

Anode

The grinding of anode materials by means of our agitator bead mills forms a key role in the production of batteries with improved performance, efficiency and service life. This process enables the production of high-quality anode materials, which form the basis for high-performance and reliable batteries that can be used in a wide range of applications.

Our advanced technology is used to break down and homogenize anode materials such as graphite or silicon into extremely fine particles. This in turn leads to increased performance and improved efficiency of the batteries.

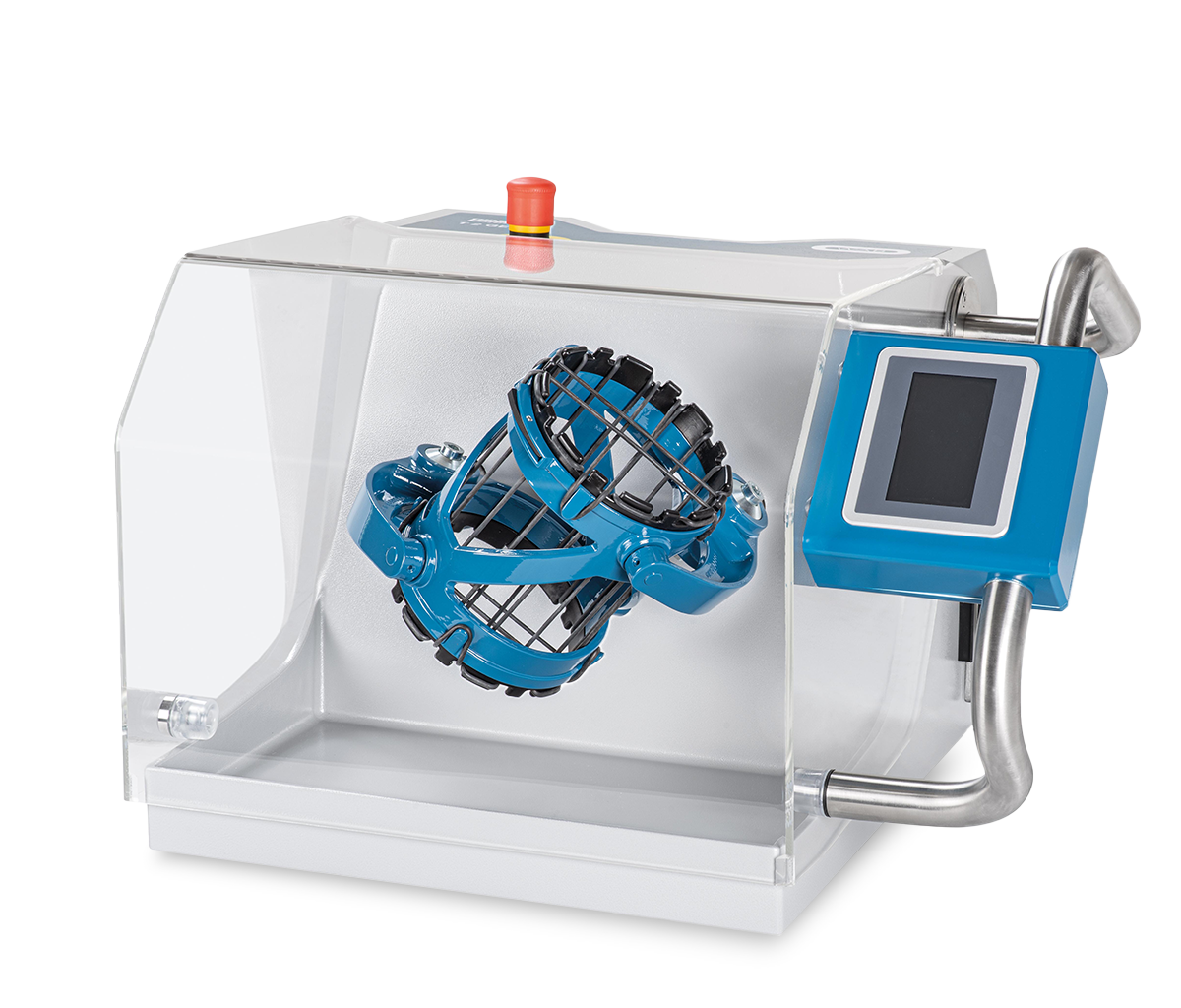

Battery materials

Dry mixing of battery materials is a method of mixing solid components of a battery without liquids. Advantages are efficiency, solvent avoidance and homogeneity. Challenges here are mixing quality, agglomerates, contamination risks and process control. Thanks to our three-dimensional shaker mixers, these requirements for the mixing process are ensured.

Ion coating

The use of our mixers in ion coating makes it possible to control the thickness and composition of the coating precisely and homogeneously. This is particularly important when it comes to producing specific properties such as hardness, abrasion resistance, adhesion and optical properties. Fine-tuned control of the mixing and coating process allows tailor-made coatings to be developed.

Fuel cell

Fuel cells are electrochemical devices that convert chemical energy directly into electrical energy by generating a continuous stream of electrically charged particles (ions). They are based on the principle of electrochemical reaction between a fuel and an oxidant. This reaction generates electrical energy.

The production of electrolyte membranes (e.g. proton exchange membranes - PEM) for fuel cells requires a fine particle structure. This is where our agitator bead mills are used in wet grinding.

Insulating materials

Overall, the mixing of insulating materials plays an important role in the manufacture of products to improve thermal, electrical and mechanical properties. It enables the development of materials that meet the requirements in various industrial sectors and lead to innovative solutions for modern challenges.

Cathode

Our agitator bead mills are used to reduce the particle size of cathode materials and increase their surface area. This improves the reaction kinetics, resulting in a more efficient electrochemical reaction during the battery charging and discharging process. Higher capacity, faster charging times and longer battery life result.

Our technology is used to grind and homogenize cathode materials such as lithium iron phosphate (LiFePO₄) or lithium nickel cobalt oxide (LiNiCoO₂) into ultra-fine particles to maximize battery performance and efficiency.

Carbon nanotubes

Carbon nanotubes (CNTs) are honeycomb-like tubes with a diameter of a few nanometers. By disperising them in our agitator bead mills, the powder from agglomerated carbon nanotubes can be seperated and stabilised.The released surface area and the associated enormous viscosity increase during the process require a controlled dispersion process. The targeted dispersion enables the physical, electrical, mechanical or conductive properties to be changed - up to the orientation of the carbon nanotubes in the final application.

Magnetic materials

Our three-dimensional shaker mixers master the mixing of magnetic materials with ease. Be it in the production of permanent magnets, in electronics, medical technology or even other industrial applications.The mixing of magnetic materials requires a careful approach in order to achieve the desired magnetic properties and at the same time to ensure a homogeneous structure. After mixing and shaping, it is necessary to sinter the materials, that is, to compact them under high temperatures and pressures. This helps to stabilize and optimize the magnetic properties.

Multilayer ceramic capacitors

The use of our agitator bead mills in the production of multilayer ceramic capacitors from finely ground granules enables precise control over particle sizes, distribution and consistency. This influences electrode adhesion, sintering temperature control and the addition of additives to improve material properties. The resulting homogeneous ceramic structure enables higher performance and reliability of the capacitors.

Photovoltaics

The grinding with our agitator bead mills of photovoltaic materials plays an important role in the production of solar cells and other photovoltaic components. This process enables the efficient grinding and dispersion of materials such as semiconductors and pigments to maximize the absorption of sunlight and optimize the performance of solar cells.

Separator

A separator provides the insulating barrier between the anode and cathode of a battery, thereby preventing the short circuit within the battery. Nevertheless, it must allow the flow of ions within the battery. Ceramic coated films are often used for this purpose. To achieve a thin yet highly efficient ceramic coating, our agitator bead mills are used.

Improvement of dielectric properties

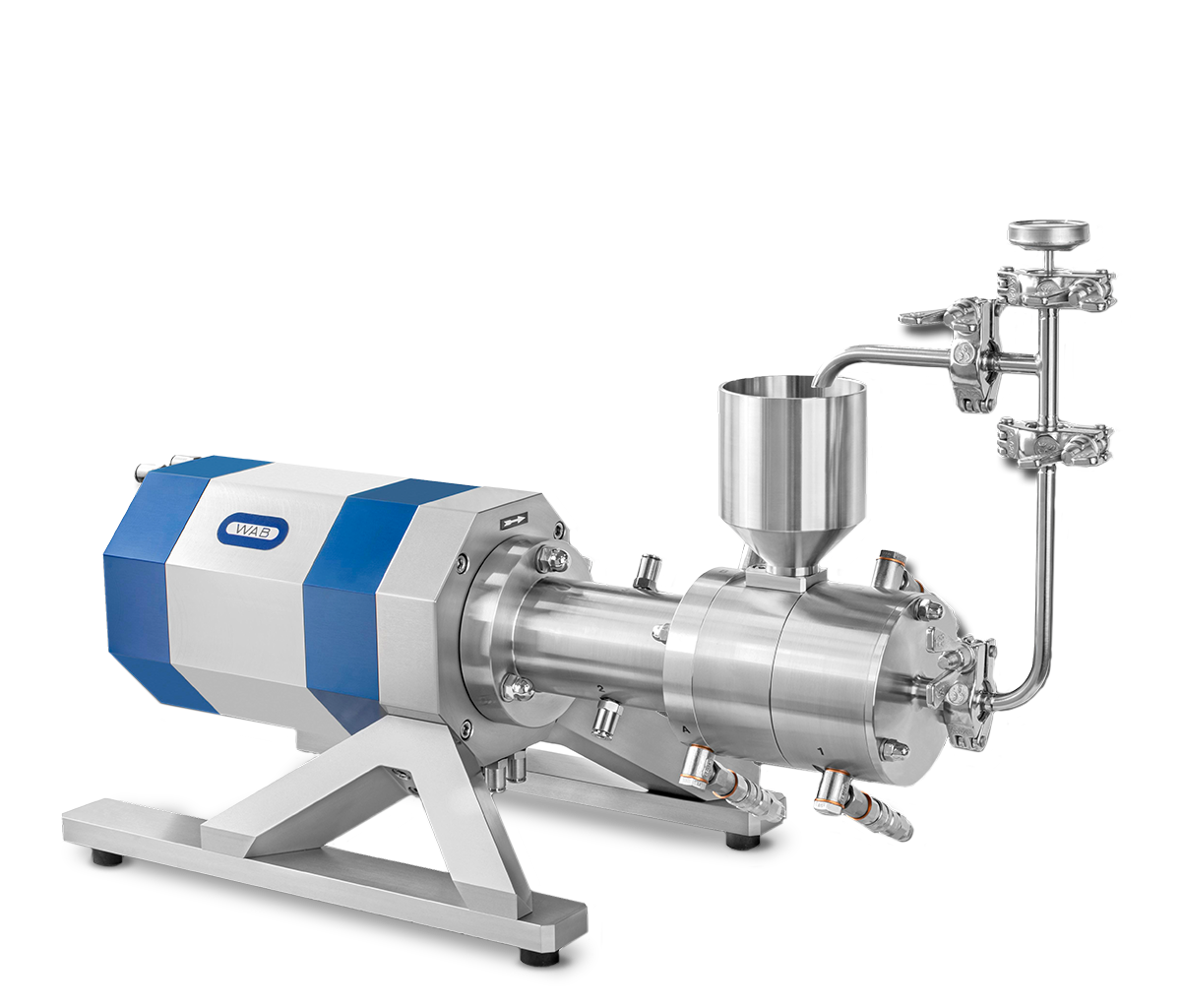

Our WAB IMPA°CT REACTOR embodies the fusion of science and technology and opens up completely new perspectives for the production of dielectric materials. Precise control of the raw material morphology and exact control of particle collisions allow desired shapes and structures to be influenced. This leads to an impressive increase in dielectric constants, minimization of dielectric loss factors and optimized insulation properties.

Additives

Our WAB IMPA°CT REACTOR opens you a new dimension in electrode material synthesis. This groundbreaking technology not only accelerates the synthesis process, but also increases the concentration of the electrode material. The result: an exponential increase in productivity and significant cost savings. Our WAB IMPA°CT REACTOR enables also the addition of additives for homogeneous electrodes, all from one plant.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our comprehensive portfolio is sure to contain the ideal model for your most demanding product.

Mechanochemical reactor

WAB IMPA°CT REACTOR

An inductively heated mechanochemical reactor for continuous mechanochemistry

Laboratory Agitator Bead Mill

DYNO-MILL UNI LAB

The laboratory agitator bead mill enables the use of DYNO-MILL UBM and ECM-AP technology and is ideal for R&D

Universal Agitator Bead Mill

DYNO-MILL UBM

Efficient dispersion and fine grinding solutions for your products

Special Agitator Bead Mill

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Laboratory Agitator Bead Mill

DYNO-MILL MULTI LAB

The laboratory agitator bead mill is flexible in terms of grinding chamber size, material selection and grinding technology

Disc Agitator Bead Mill

DYNO-MILL KD

The mill is suitable for numerous applications and all types of grinding media materials

Laboratory Agitator Bead Mill

DYNO-MILL ECM-AP 05

The high-performance laboratory mill produces the finest and narrowest particle distributions down to the nanometer range

High-Performance Agitator Bead Mill

DYNO-MILL ECM-AP

The ideal agitator bead mill for high throughputs and highly viscous products

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.