Grinding and dispersion technology

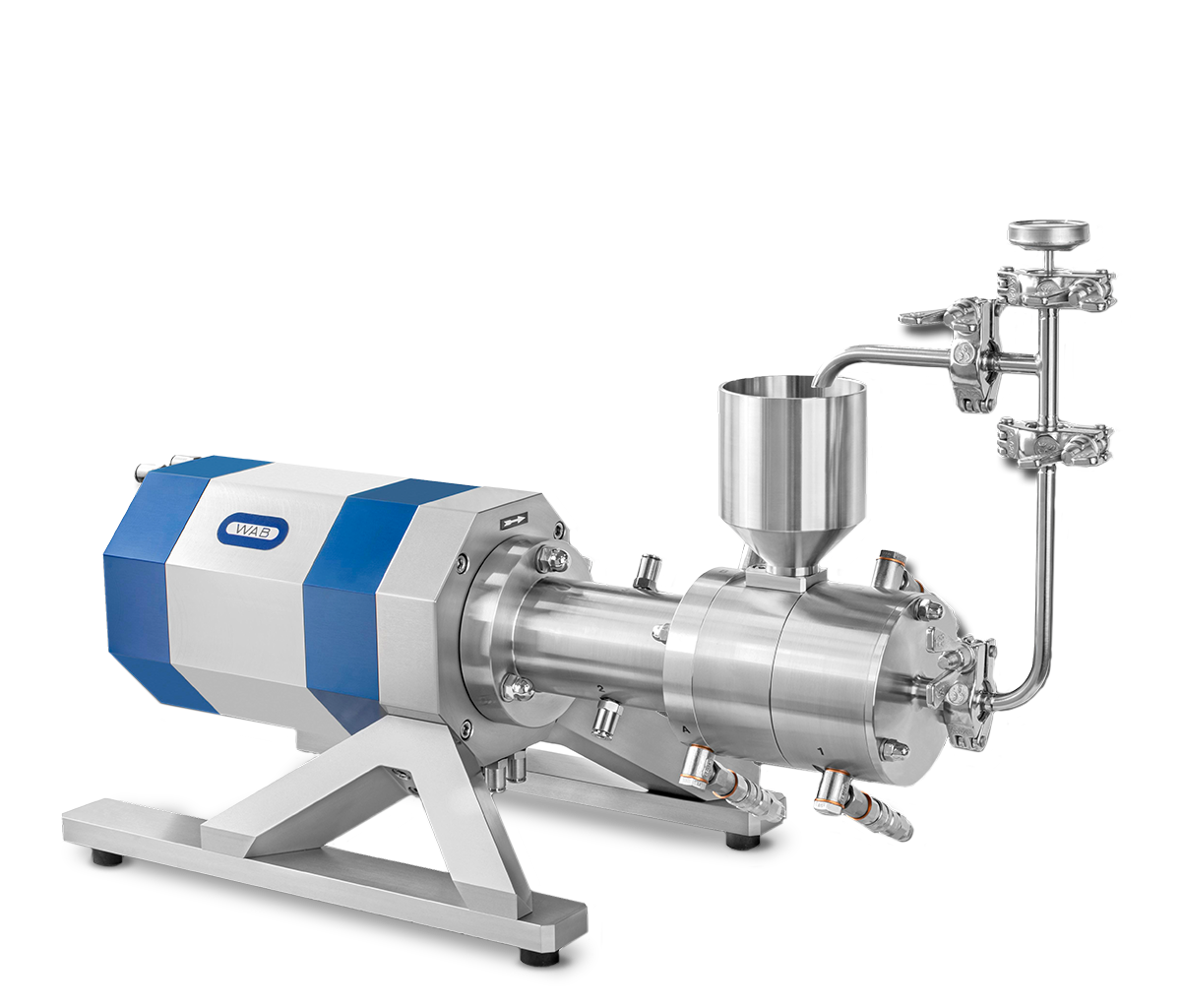

Disc Agitator Bead Mill

DYNO-MILL ECO 5

The ideal disc agitator bead mill for small productions

Industries

Practical and cost-effective for small productions

The practical agitator bead mill for small-scale production is used for continuous dispersion and wet grinding of low-viscosity to viscous, pumpable products.

Functionality

The DYNO-MILL ECO 5 is equipped with the traditional KD agitator discs. The energy required for dispersion and grinding is transferred to the grinding media via easily replaceable agitator discs mounted on the agitator shaft. The product to be processed is fed to the mill via an external feed pump. The grinding media are retained in the mill by means of a dynamic gap separator. The gap width is adjusted with distance standard parts according to the grinding media sizes. Grinding media of various materials and sizes (0.5-2.5 mm) can be used.

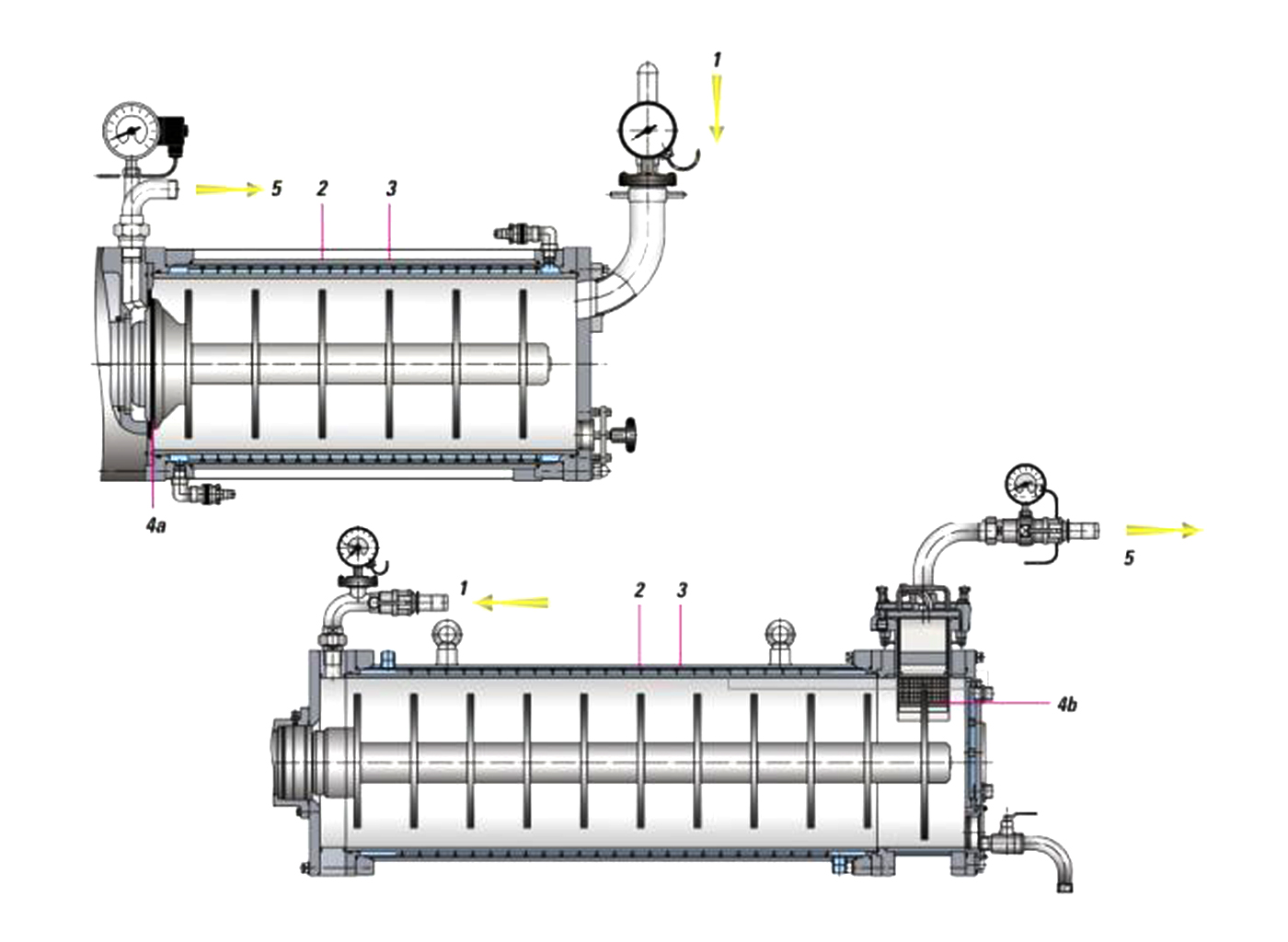

Proven grinding chamber system

- Product inlet/grinding bead inlet

- DYNO agitator discs

- Coolable grinding container with easily replaceable grinding cylinder

- Dynamic gap separator

- Product outlet

Features

- Ideal for passage mode with consistent efficiency and for achieving the narrowest grain spectra in the micron range

- The ideal equipment for every product with the choice of a wide range of materials for the components in contact with the product

- Small process volume and ideal cooling properties with forced cooling water flow in the outer jacket allow processing of temperature-sensitive products

- Easy handling - the DYNO-MILL ECO 5 can be disassembled in just a few steps and a quick changeover to another mill configuration is guaranteed

- Easy operation and setting of operating parameters

- Due to the constant grinding concept, scale-up to all production mills of the DYNO-MILL KD series is possible.

- Low operating and maintenance costs

Download

Find more information about our disc agitator bead mill in compact form as PDF file. Practical and cost-effective for small-scale production.

Technical specifications

| Type | ECO 5 |

|---|---|

| Grinding chamber volume (l) | 5 |

| Capacity range (l/h) | 20-200 |

| Mill drive (kW) | 10 |

| Cooling water throughput (L/h) | 800-1000 |

| Weight (kg) | 250-300 |

| Dimension L x W x H (mm) | 1001 x 797 x 654 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.