Higher yield and no need for solvents

Paracetamol is a drug that is used to relieve pain and reduce fever. Compared to the current solvent-based production process, the process on the DYNO-MILL RESEARCH LAB achieves a higher yield and at the same time enables the removal of solvents during the chemical reaction.

Mechanical force

The application of high energy through shear, impact and shock enables a mechanochemical reaction.

Faster reaction

The process time for the synthesis with the DYNO-MILL RESEARCH LAB was 30 minutes compared to 1 hour with a solvent-based process.

Better quality

The yield for this reaction was 89 % compared to 74 % for a solvent-based batch tank reaction.

Scalability

This is the first application of the DYNO-MILL technology for the sustainable mechanochemical synthesis of acetaminophen, known as paracetamol. Comparable studies with conventional ball mills enabled the production of only a few milligrams. However, these small-scale results are not scalable. The optimized solvent-free methodology based on the DYNO-MILL technology delivered a final product on the scale of several centigrams, proving its suitability for industrial scale-up.

Solvent-free reaction

Compared to the current solvent-based production process, the proposed process achieves a higher yield while eliminating the need for solvents in the chemical reaction, thereby reducing one of the main factors for waste generation.

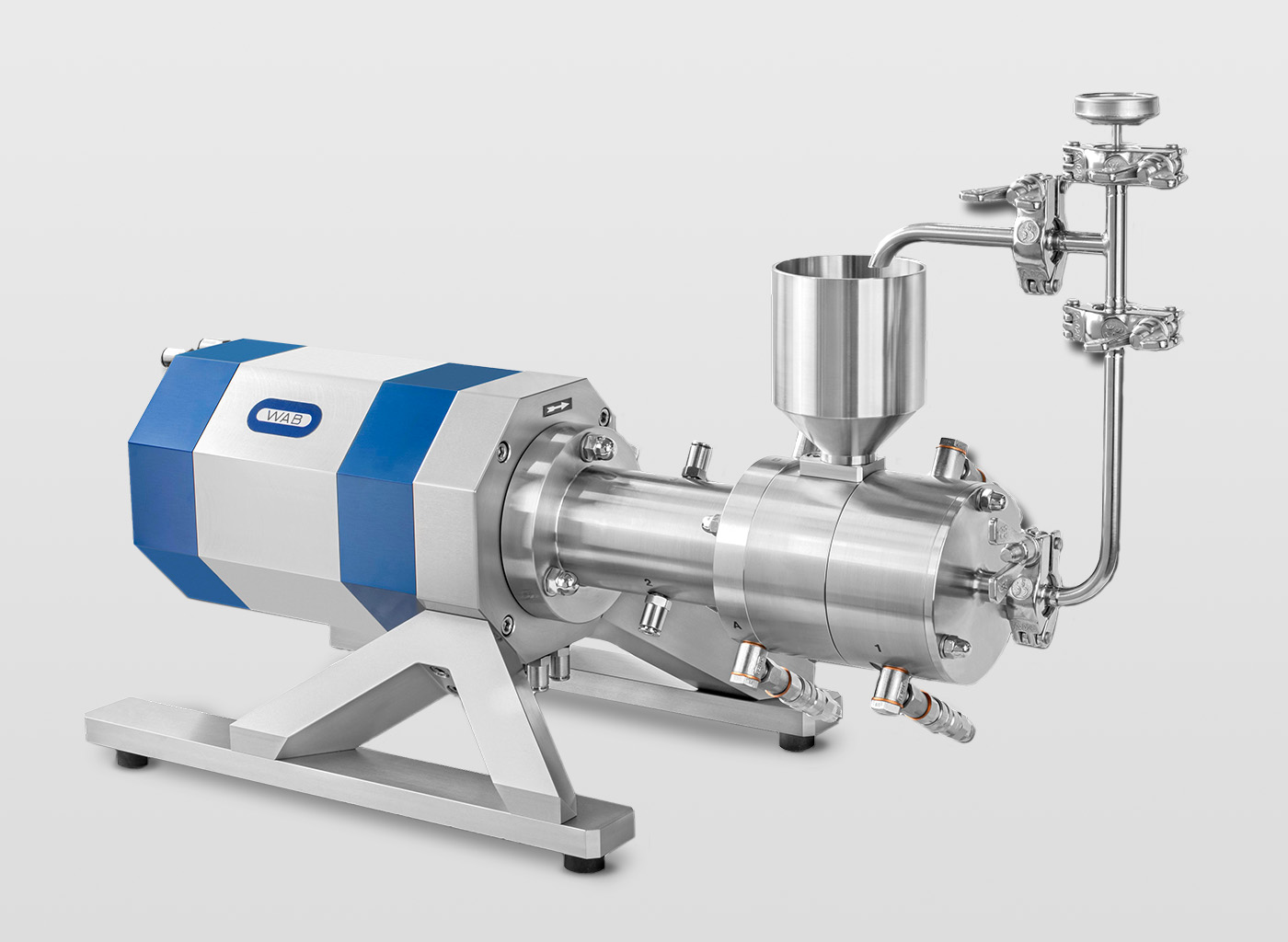

DYNO-MILL RESEARCH LAB

The solution for achieving reactions in flow chemistry with less solvent and lower energy consumption.

Download

Would you like to find out more? You can find more information in the paper.

The research was done by R. Geib and Prof. Dr. L. Gremaud, School of Engineering and Architecture of Fribourg (Switzerland), Department of Chemistry - Institute of Chemical Technology and Prof. Dr. E. Colacino, ICGM, Université Montpellier (France).

https://chemistry-europe.onlinelibrary.wiley.com/doi/full/10.1002/cssc.202301921

Contact Switzerland

Would you like information or advice on our products? Our team is at your disposal.

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.