Grinding and dispersion technology

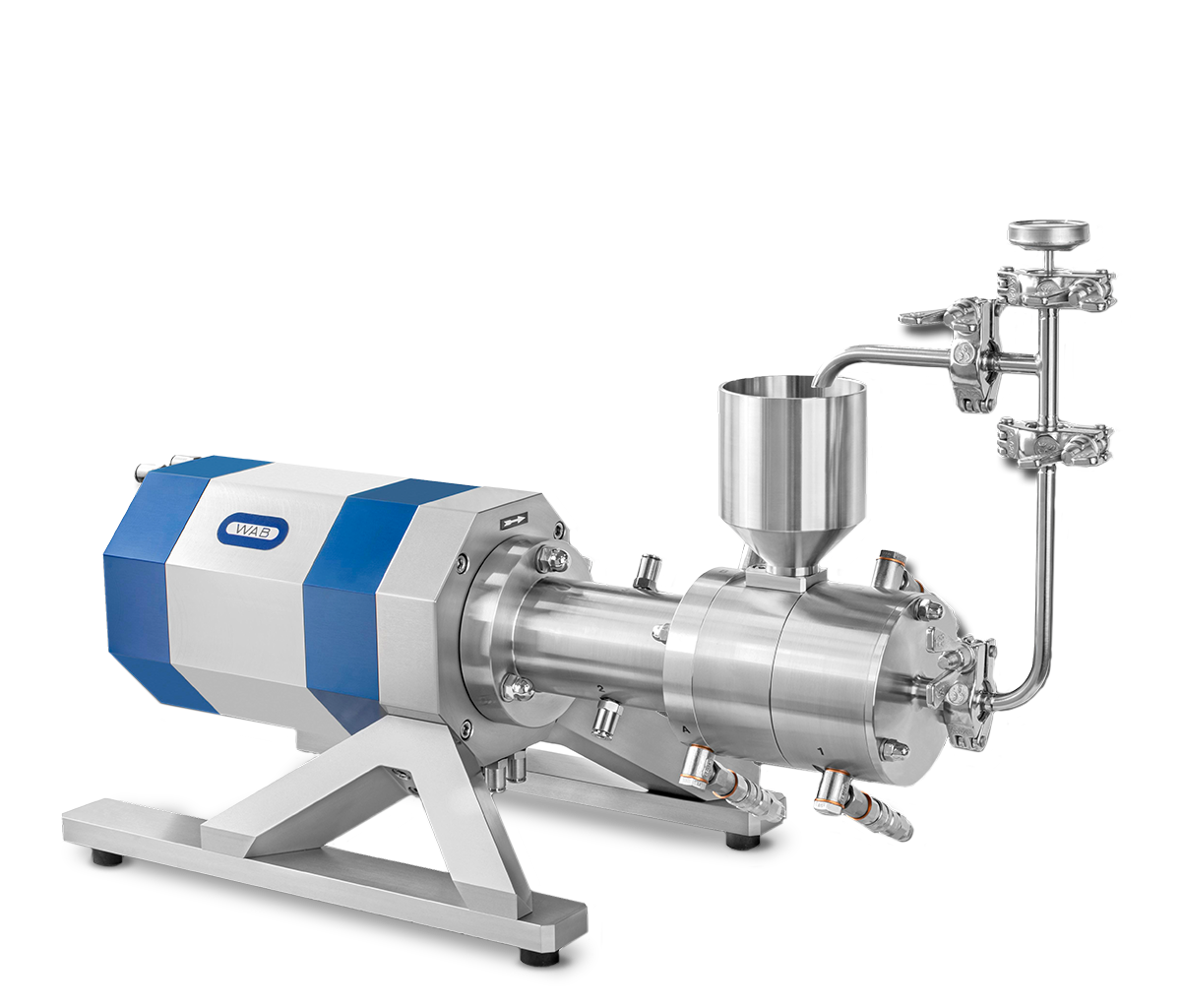

Laboratory Agitator Bead Mill

DYNO-MILL UNI LAB

The laboratory agitator bead mill enables the use of DYNO-MILL UBM and ECM-AP technology and is ideal for R&D

Industries

Specially developed for the laboratory environment

The DYNO-MILL UNI LAB covers a broad spectrum: it produces dispersions and fine grinds down to the nanometer range quickly and efficiently and is suitable for low- to high-viscosity products.

The compact agitator bead mill can be operated with two different grinding principles. In the standard version, it is the scale-up model for the DYNO-MILL UBM series. The housing allows the use of a second grinding chamber with the world-renowned DYNO-ACCELERATOR technology for unmatched flexibility and cost-effectiveness in the laboratory.

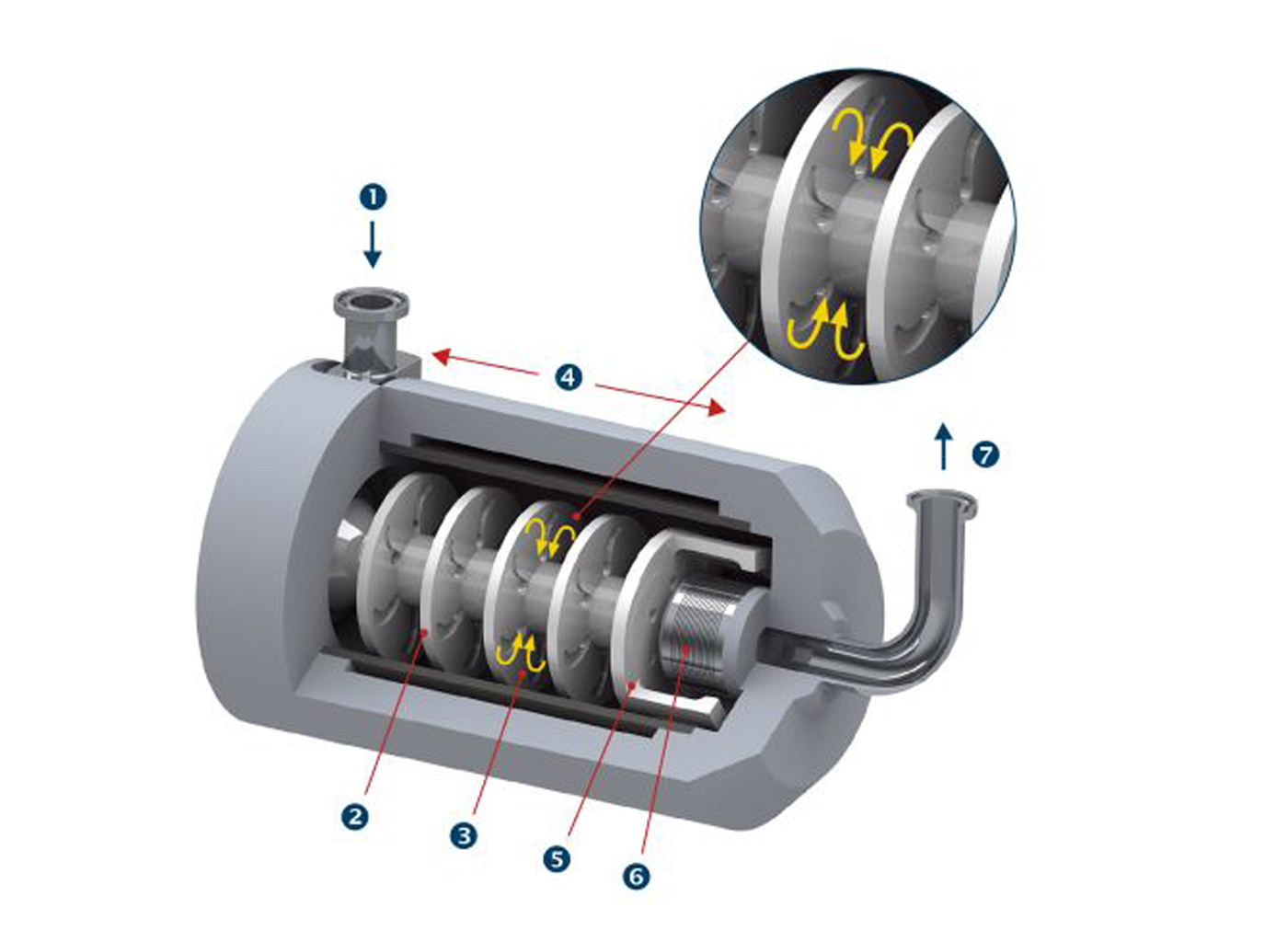

Functionality

The DYNO-MILL UNI LAB uses the newly developed DYNO-DISC BC agitator discs with their unique grinding media channels (bead channels) in combination with a closed outer contour.

The grinding media channels ensure the effective acceleration of the grinding media along a precisely defined path. They build up two effective, counter-rotating grinding circuits between each of the DYNO-DISC agitator discs.

Novel grinding chamber system

- Product inlet

- DYNO-DISC BC (Bead Channel)

- Grinding circuits that operate in opposite directions

- Even distribution of the grinding beads in the active grinding chamber

- DYNO-ROTOR BS (Bead Separation)

- Screen for high throughputs

- Product outlet

Features

- Suitability for high throughputs and highly viscous products

- Wide range of materials for optimum machine equipment

- Suitable for temperature-sensitive products thanks to effective cooling of the grinding chamber

- Suitability for steel, glass and ceramic grinding media

- Uniform grinding media density distribution in the grinding chamber for maximum efficiency

- Efficient grinding with grinding media from ø 0.2 mm (with a grinding chamber exchange unit DYNO-ACCELERATOR, grinding media from ø 0.1 mm can also be used)

- Long screen life

- Suitability for passage and circuit mode

- Simple and ergonomic machine handling incl. maintenance work

- Fast product changeover

- Wide range of control solutions

Download

Find more information about our laboratory agitator bead mill in compact form as PDF file. Cost-efficient and easy-to-use solution for your products.

Technical specifications

| Type | UNI LAB | UBM 5 | UBM 20 | UBM 50 | UBM 100 |

|---|---|---|---|---|---|

| Grinding chamber volume (liters) | 0,53 | 6.0 | 19,6 | 55,3 | 94,6 |

| Active grinding chamber volume (l) | 0,41 | 5.2 | 17,4 | 50,6 | 86,6 |

| Mill drive (kW) | 4 | 11 | 30 | 55 | 90 |

| Cooling water throughput (L/h) | 250-400 | 600-1000 | 800-2000 | 2000-4000 | 2500-4500 |

| Weight (kg) | 120-140 | 750-850 | 1150-1250 | 1900-2100 | 2800-3100 |

| Dimension L x W x H (mm) | 895 x 725 x 730 | 1630 x 865 x 1650 | 1185 x 1025 x 1800 | 2265 x 1290 x 2080 | 2560 x 1305 x 2270 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.