Grinding and dispersion technology

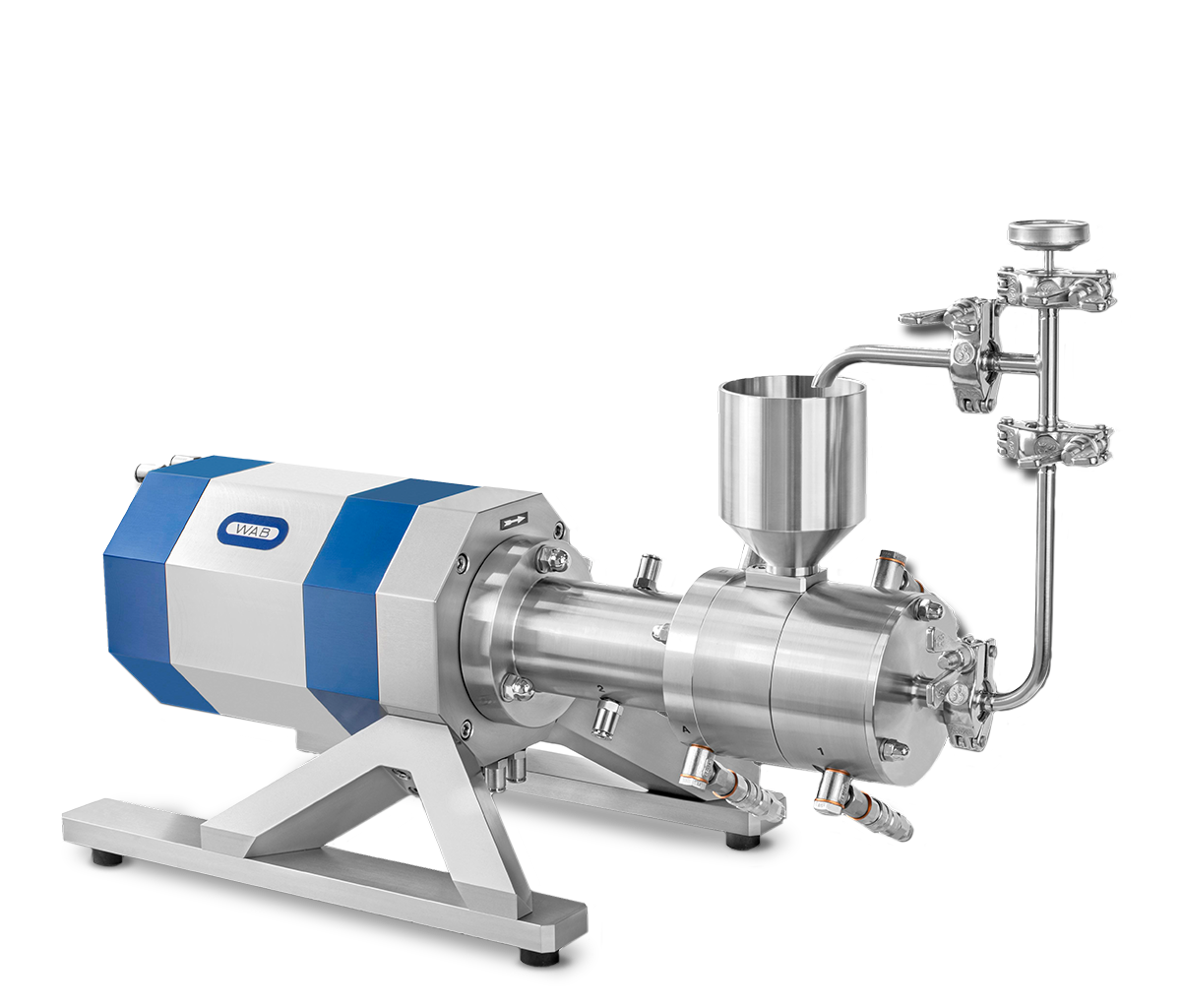

Laboratory Agitator Bead Mill

DYNO-MILL MULTI LAB

The laboratory agitator bead mill is flexible in terms of grinding chamber size, material selection and grinding technology

Industries

Laboratory mill with unique flexibility

As the name suggests, this laboratory mill is amazingly flexible. With this multi-talent, you can vary grinding chamber size, material selection and grinding technology across an enormous breadth.

If you want to disperse or comminute materials with a wide variety of properties and batch quantities discontinuously or continuously, the DYNO-MILL MULTI LAB is the first choice. It is the ideal agitator bead mill for very small batches in research and development and for batches in small-scale production.

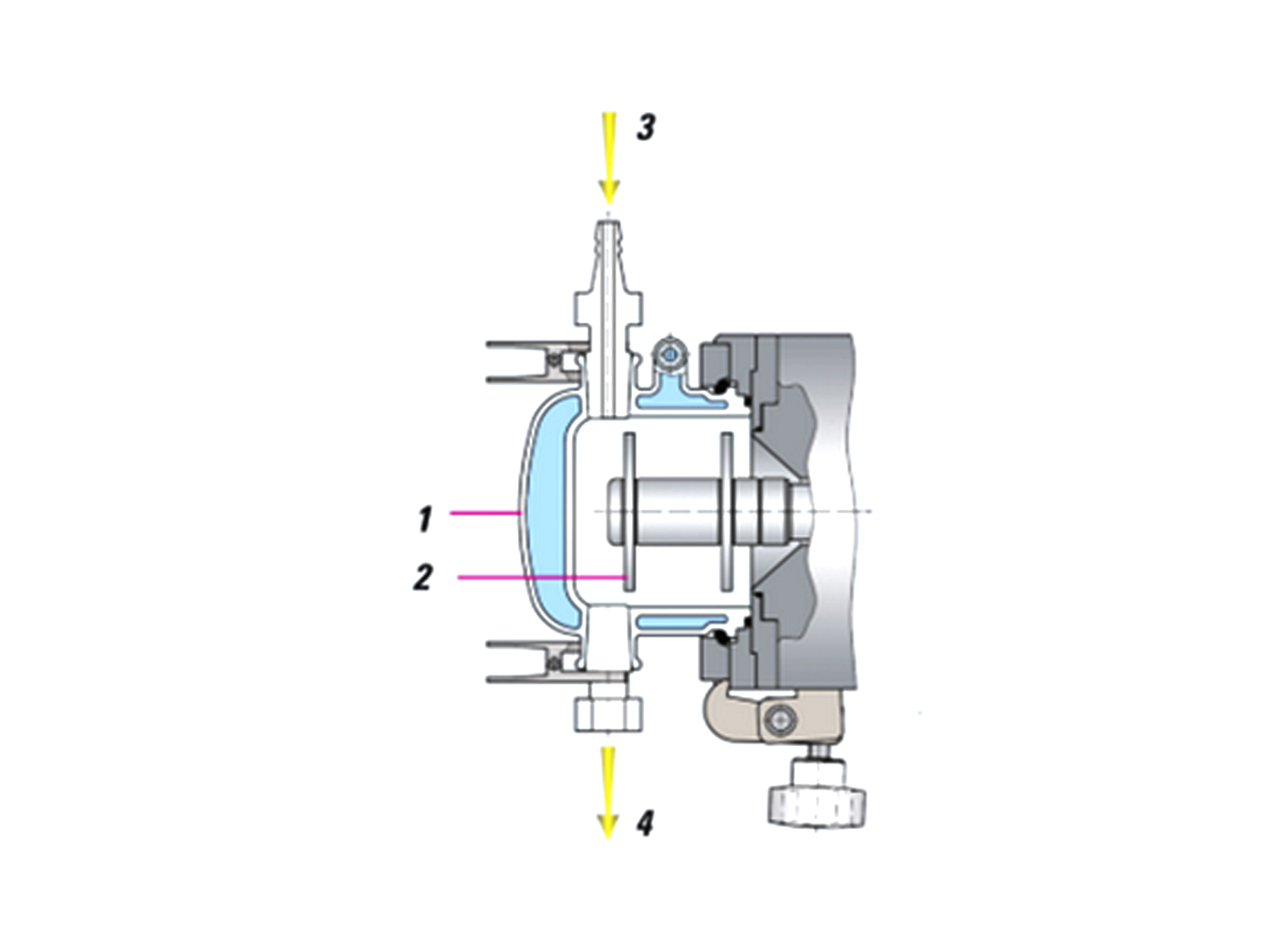

Mode of operation: Discontinuous operation

Two grinding vessels with a volume of 0.15 l and 0.3 l have been specially developed for processing low-viscosity suspensions in batch sizes of 85 ml and 170 ml respectively in discontinuous operation. After grinding, the material to be ground must be separated from the grinding media by washing. Discontinuous operation is used in particular for cell disruption in microbiology, but also for processing active pharmaceutical ingredients.

Proven grinding chamber system

- Coolable grinding container

- DYNO agitator disc

- Product inlet

- Product outlet

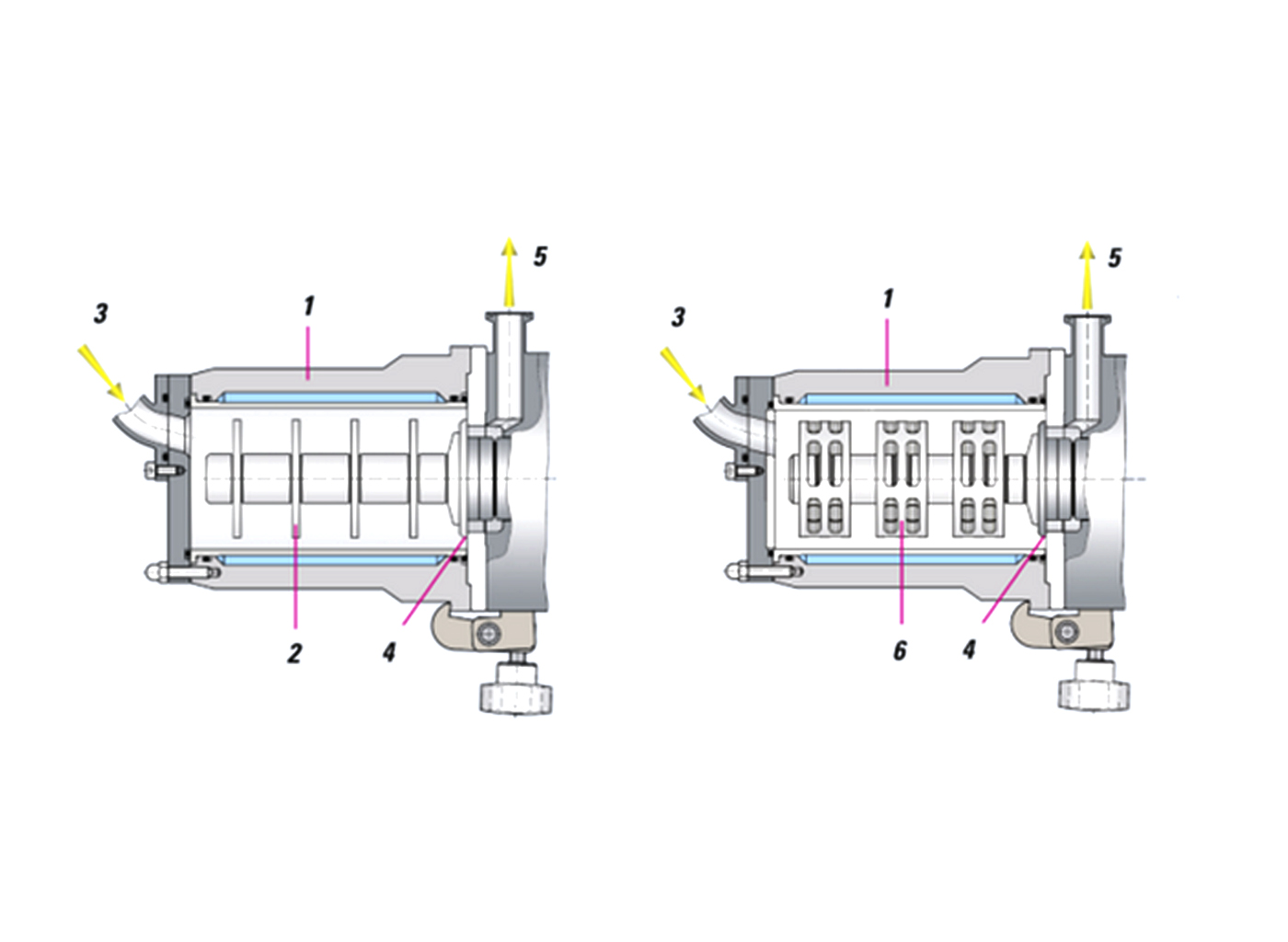

Mode of operation: Continuous operation

For the processing of low-viscosity to viscous, pumpable products with batch sizes of >500 ml, grinding containers with a volume of 0.15 l, 0.3 l, 0.6 l and 1.4 l can be used. With a feed pump placed next to the mill, the ground material of the DYNO-MILL MULTI LAB is fed into the grinding chamber. The grinding media are retained in the grinding chamber by means of a dynamic gap separator, which allows the use of grinding media with a ø of 0.1 to 2.5 mm.

For very high throughputs in the circulation mode, but also in the passage mode, the grinding principle ECM with the DYNO-ACCELERATOR is used. This version is available in the volume size 0.6 l.

Proven grinding chamber system

- Coolable grinding container with easily replaceable grinding cylinder

- DYNO agitator disc

- Product inlet

- Dynamic gap separator

- Product outlet

- DYNO-ACCELERATOR

Features

- Ideal for micro approaches in research and development

- Suitable for small production

- Discontinuous or continuous operation with the same laboratory mill

- Two grinding principles in one mill with the DYNO agitator disc and the patented DYNO-ACCELERATOR

- Due to the constant grinding concept, scale-up to all production mills of the DYNO-MILL with the same principle is possible

- The ideal equipment for every product with the selection of a wide range of materials for the product-wetted wearing parts

- Long service life and metal-free grinding due to the use of high-quality ceramics

- Small process volume and ideal cooling properties allow processing of temperature-sensitive products

- Easy handling - the DYNO-MILL MULTI LAB can be disassembled and reconfigured in just a few steps

- GMP compliant design

- Very easy cleaning with little cleaning required

- Ergonomic design of the mill

- Sophisticated control concept

- Wide range of control solutions

Customized solutions

Our experience helps us to meet your process needs for projects with different and special requirements and to offer you a tailor-made solution such as the agitator bead mill DYNO-MILL Pharma.

Download

Find more information about our laboratory agitator bead mill in compact form as PDF file. Ideal for research and development.

Technical specifications

| Type | Discontinuous | Discontinuous | Continuous | Continuous | Continuous | Continuous | Continuous |

|---|---|---|---|---|---|---|---|

| Grinding chamber volume (liters) | 0,15 | 0,3 | 0,15 | 0,3 | 0,6 | 0,6 | 1,4 |

| Minimum batch volume (ml) | 85 | 170 | 500 | 600 | 800 | 800 | 2000 |

| Grinding system, ø (mm) | KD stirring discs, 64 | KD stirring discs, 64 | KD stirring discs, 64 | KD stirring discs, 64 | DYNO-Accelerators, 64 | KD stirring discs, 64 | KD stirring discs, 80 |

| Mill drive (kW) | 3.3-4.0 | 3.3-4.0 | 3.3-4.0 | 3.3-4.0 | 3.3-4.0 | 3.3-4.0 | 3.3-4.0 |

| Cooling water throughput (L/h) | 250-400 | 250-400 | 250-400 | 250-400 | 250-400 | 250-400 | 250-400 |

| Weight (kg) | 95-125 | 95-125 | 95-125 | 95-125 | 95-125 | 95-125 | 95-125 |

| Dimension L x W x H (mm) | 680 x 740 x 580 | 680 x 740 x 580 | 680 x 740 x 580 | 680 x 740 x 580 | 680 x 740 x 580 | 680 x 740 x 580 | 680 x 740 x 580 |

We are here for you

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.