As little as possible as much as necessary

Our application areas have a fascinating variety

Fertilizer

In the production of fertilizers, our agitator bead mills help to increase the efficiency of nutrient uptake by plants and reduce the environmental impact of fertilizers. By developing fertilizer formulations with optimized particle size, solubility and release properties, more sustainable and efficient fertilizer use is achieved.

Fungicide

Our agitator bead mills lead to optimization of particle size, particle distribution, solubility and miscibility of active ingredients in the production of fungicides. Precise particle size and particle distribution allows for better adhesion to plant surfaces, improved leaf coverage and targeted application to the plant. This in turn leads to more efficient use of active ingredients and minimized environmental impact.

Herbicide

Our agitator bead mills lead to optimization of particle size, particle distribution, solubility and miscibility of active ingredients in the production of herbicides. Precise particle size and particle distribution enable better weed control through improved surface absorption properties. This in turn leads to more efficient use of active ingredients and minimized environmental impact.

Insecticide

Our agitator bead mills lead to optimization of particle size, particle distribution, solubility and miscibility of active ingredients in the production of insecticides. Precise particle size and particle distribution enable better adhesion and protection of the plant against pests. This in turn leads to more efficient use of active ingredients and minimized environmental impact.

Application Cases

Special applications

Discover application examples where WAB-GROUP solutions have proven themselves.

Discover the right products

Our comprehensive portfolio is sure to contain the ideal model for your most demanding product.

Laboratory Agitator Bead Mill

DYNO-MILL UNI LAB

The laboratory agitator bead mill enables the use of DYNO-MILL UBM and ECM-AP technology and is ideal for R&D

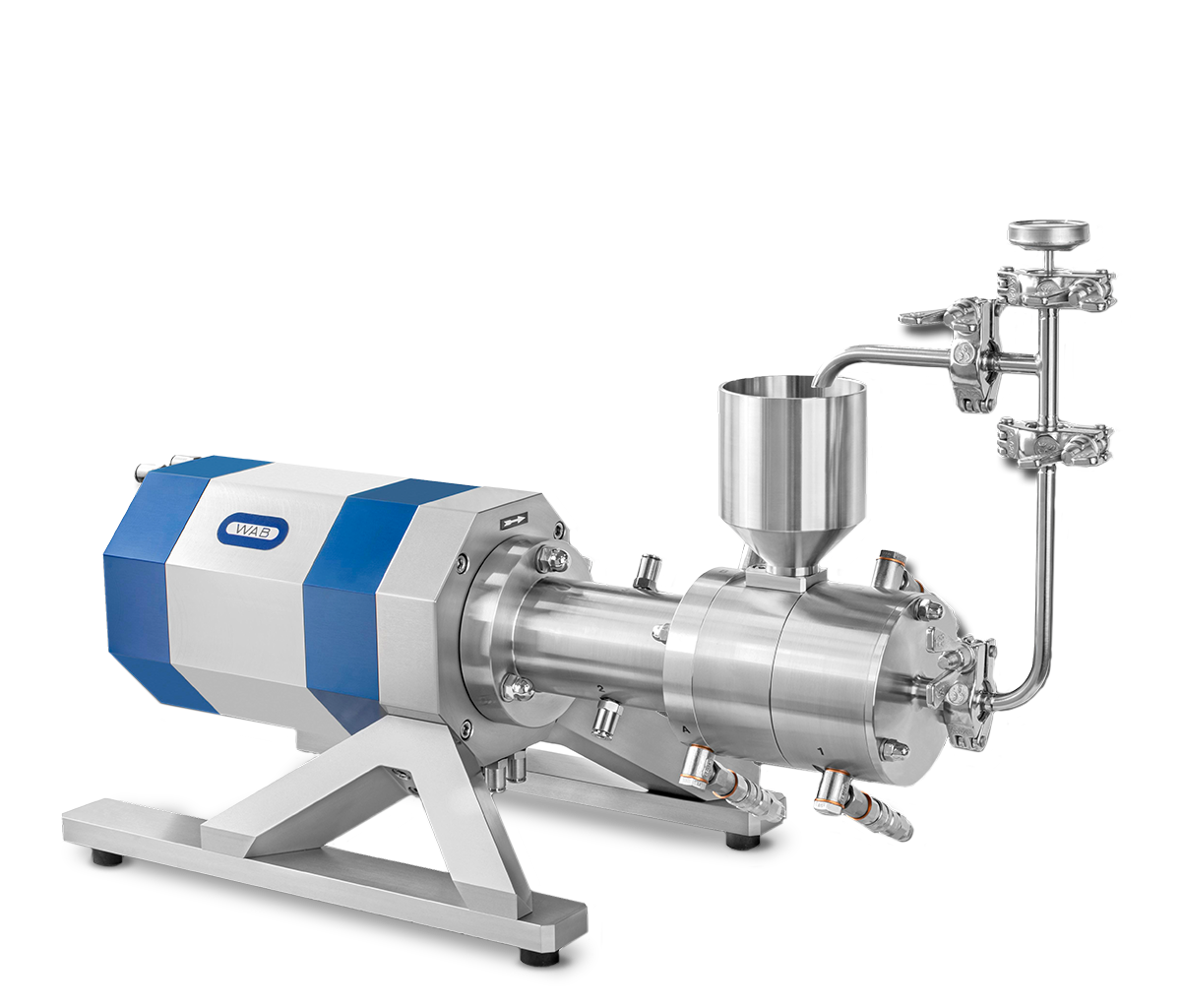

Universal Agitator Bead Mill

DYNO-MILL UBM

Efficient dispersion and fine grinding solutions for your products

Special Agitator Bead Mill

DYNO-MILL RESEARCH LAB

The perfect agitator bead mill for research and development with a grinding chamber volume of 80 ml

Laboratory Agitator Bead Mill

DYNO-MILL MULTI LAB

The laboratory agitator bead mill is flexible in terms of grinding chamber size, material selection and grinding technology

Disc Agitator Bead Mill

DYNO-MILL KD

The mill is suitable for numerous applications and all types of grinding media materials

Laboratory Agitator Bead Mill

DYNO-MILL ECM-AP 05

The high-performance laboratory mill produces the finest and narrowest particle distributions down to the nanometer range

High-Performance Agitator Bead Mill

DYNO-MILL ECM-AP

The ideal agitator bead mill for high throughputs and highly viscous products

Always there for you

Our services

- Expert AdviceExpert Advice

- Spare PartsSpare parts

- RepairsRepairs

- TrialsTrials

- Trainings and SeminarsTrainings and seminars

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.

"*" indicates required fields