Global rollout of the newly defined vision, mission and corporate values

This week, the newly defined vision, mission and corporate values of WAB-GROUP were presented in a worldwide team event.

Foundation of the new subsidiary

WAB Israel Corp Ltd

WAB-GROUP expands and establishes a new subsidiary.

Change of Management Willy A. Bachofen GmbH

Henryk Sommer takes over as the new Managing Director of Willy A. Bachofen GmbH in Nidderau.

WAB India Pvt. Ltd. moves into new office building

New site in Mumbai includes state-of-the-art Process Technology Centre (PTC).

New address of Willy A. Bachofen AG in China (Shanghai)

New sales office of WAB MACHINERY (Shenzhen) Co., Ltd. opens its doors.

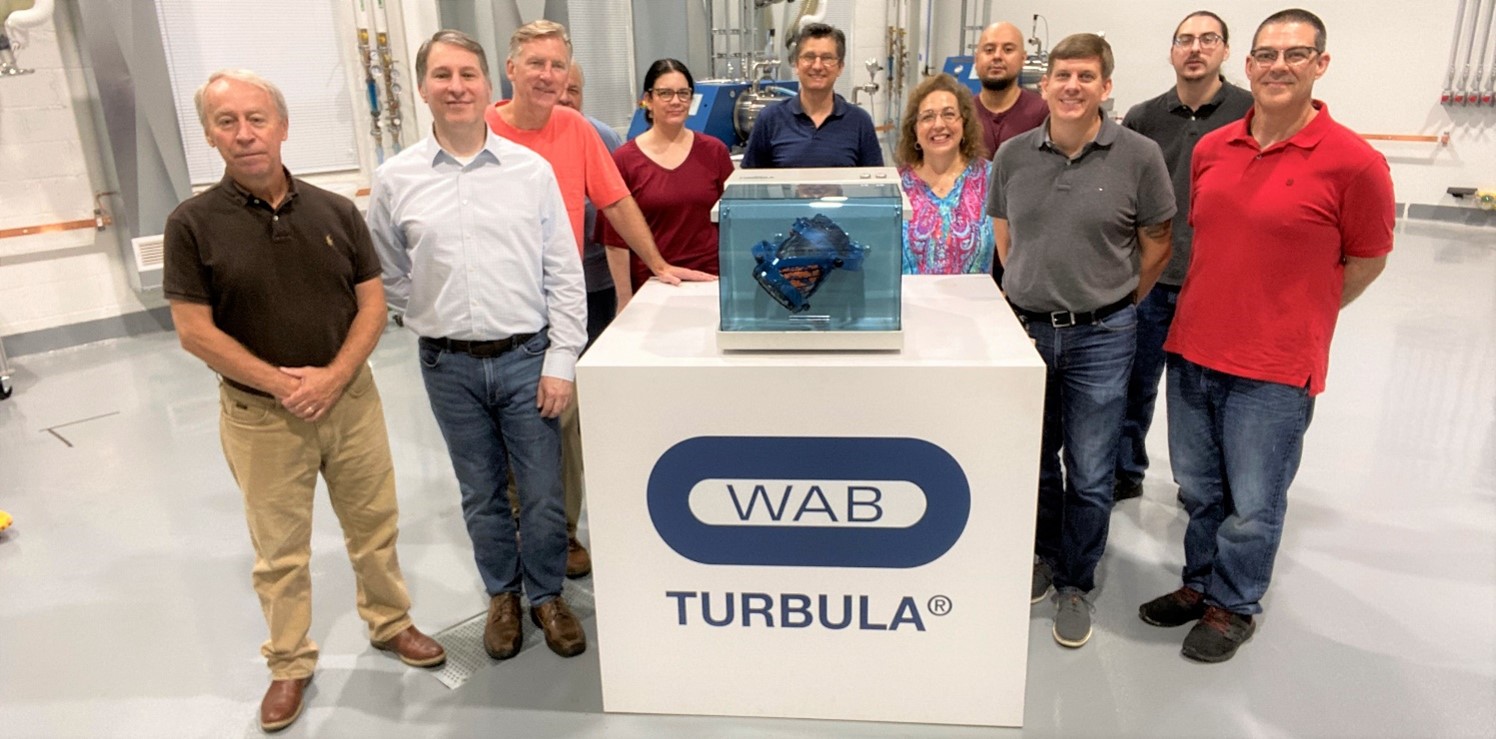

WAB US Corp. acquires TURBULA exclusive rights in North America

YOUR RELIABLE PARTNER

WE ARE HERE FOR YOU

With our local sites and technical specialists on site, we are happy to be at your service as a competent engineering company and proven process expert.

"*" indicates required fields